10V Alloy Steel Powder for Cladding: The “King of Wear Resistance” with Stable 62HRC Hardness

In modern industry, equipment wear remains one of the main causes of reduced productivity and shortened service life. 10V alloy steel powder for cladding, developed with advanced metallurgy and optimized for the Plasma Transferred Arc Welding (PTA) process, has become a benchmark solution for wear-resistant hardfacing. Its unique composition and reliable performance make it a preferred choice for industries requiring longer equipment life and reduced maintenance costs.

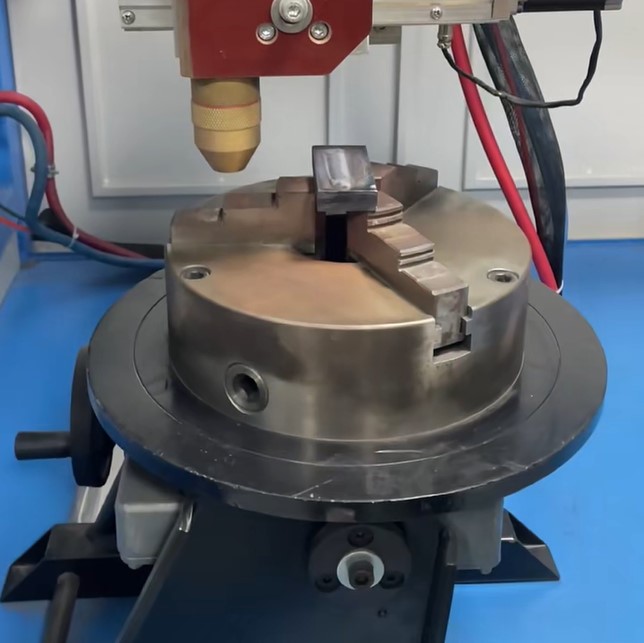

PTA welding process using 10V alloy steel powder

Key Advantages of 10V Alloy Steel Powder

1. High Carbon + High Vanadium Design

The elevated carbon content significantly enhances matrix hardness, while vanadium promotes the in-situ formation of vanadium carbides (VC). These ultra-hard particles, reaching above 2800 HV, create a wear-resistant skeleton within the cladding layer, ensuring outstanding abrasion protection even under extreme load.

2. Chromium-Molybdenum Synergy

Chromium increases hardenability, ensuring uniform hardness distribution across the cladding layer. Molybdenum strengthens resistance to corrosion and pitting, allowing the coating to perform reliably in harsh chemical or abrasive environments.

Optimized for the PTA Process

The 10V alloy steel powder for PTA cladding is engineered for consistent quality and durability:

- Stable Process Control – Precisely managed energy input minimizes the heat-affected zone and prevents cracking common in traditional welding.

- Consistent Hardness – The cladding layer maintains a stable 60–62 HRC hardness, regardless of dilution with the base material.

- Comprehensive Performance – Beyond wear resistance, the coating also demonstrates high-temperature stability and fatigue resistance, reducing unplanned downtime.

Proven Industrial Applications

The versatility of 10V alloy steel powder allows it to excel across a wide range of industries:

- Mining Machinery – Protects against severe abrasion from ores and hard minerals.

- Cement Production – Extends the service life of crushers, grinding rollers, and separator blades.

- Metallurgy – Provides reliable protection for high-temperature components such as rolling mill guides.

- Power Generation – Delivers long-term wear and corrosion resistance for boiler and turbine parts in demanding environments.

Why Choose FNS Pipeline Technology?

At FNS Pipeline Technology Co., Ltd., we don’t just supply alloy powders—we deliver complete wear-resistant solutions. Our advantages include:

- In-house R&D – Customized alloy formulations developed to match customer requirements.

- Strict Quality Control – Every batch of powder tested for particle size, chemistry, and flowability.

- Global Experience – Trusted by clients in mining, energy, and heavy industry across 30+ countries.

- Proven Value – Customers report extended component life of up to 2–3 times compared to conventional hardfacing materials, significantly reducing maintenance costs.

Frequently Asked Questions (FAQ)

Q1: What makes 10V alloy steel powder superior to conventional hardfacing alloys?

A1: Its high vanadium content forms ultra-hard vanadium carbides, offering far greater abrasion resistance than standard alloys.

Q2: Is 10V alloy steel powder limited to plasma cladding?

A2: While optimized for PTA cladding, it can also be adapted for other hardfacing methods depending on application requirements.

Q3: What hardness range can be achieved with this powder?

A3: The cladding layer consistently achieves 60–62 HRC, even under variable dilution conditions.

Q4: Which industries benefit most from 10V alloy steel powder for cladding?

A4: Mining, cement, metallurgy, and power generation are the main sectors, though it can be applied to any high-wear, high-temperature environment.

Looking for a wear-resistant cladding material that delivers proven performance?

👉 Contact FNS Pipeline Technology Co., Ltd. today to request a technical datasheet, sample, or tailored solution for your application. Our experts are ready to help extend your equipment’s service life and cut maintenance costs.