-

Cladding of Large-Diameter Pipeline Tee | Weld Overlay Solutions by FNS

Cladding of large-diameter pipeline tee plays a critical role in protecting key junctions within pipeline systems that operate in aggressive environments. At FNS Pipeline, we recently completed [...] -

Pipeline Valve Cladding with Inconel 625: Extending Valve Lifespan and Performance

In the relentless environments of modern industry, pipeline valves face constant assault from aggressive media like sour gas, corrosive seawater, and high-pressure hydrocarbons. This exposure le [...] -

Pipeline Pipe Product Processing Case: API 5L X60 Clad Pipe with Inconel 625 Overlay

In aggressive industrial environments, internal pipe cladding is a proven solution for enhancing the corrosion resistance and lifespan of pipeline products. This case highlights the application [...] -

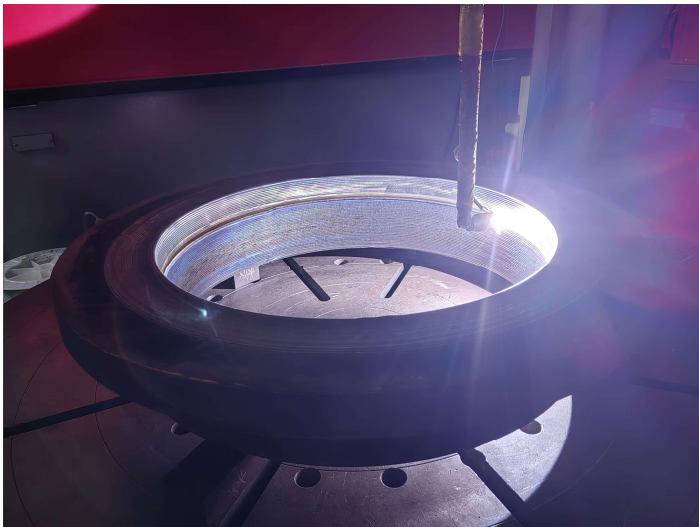

Pipeline Large Diameter Flanges Cladding(Stellite 21)

Our Large Diameter Flanges Cladding case utilizes Stellite 21 to deliver outstanding wear and corrosion resistance for demanding industrial applications. Using advanced weld overlay techniques, [...] -

Pipeline 90° long radius elbow cladding case:nickel-based alloy 625

In modern pipeline systems, elbows—especially 90° long radius elbows—are critical components subjected to severe corrosion, high temperatures, and mechanical stresses. To ensure long-term reliab [...] -

Inconel 625 Weld Overlay on A105 Pipeline Valves: Case Study of Corrosion-Resistant Cladding

In demanding industrial environments such as offshore platforms, subsea pipelines, and chemical processing plants, standard carbon steel valves often face premature failure due to corrosion and [...] -

Pipeline Flange Product Processing Case: ASTM A694 F60 + Inconel 625 (NiCrMo-3)

This project highlights the internal surface cladding of high-pressure pipeline flanges using Inconel 625 (NiCrMo-3) over ASTM A694 F60 carbon steel. Designed for critical pipeline connections i [...] -

Oil Drilling Product Processing Case: F22 75K+625(NiCrMo-3)

This case involves the advanced corrosion-resistant overlay cladding of a subsea Christmas tree body, a core component in offshore oilfield production systems. The base material, F22 75K high-st [...] -

Oil drilling Product Processing Case:4130 75k+625(NiCrMo-3)

This case highlights the cladding process of an API 6A valve body, a key component used in high-pressure oil and gas drilling operations. The base material, 4130 75K high-strength alloy steel, i [...] -

Petrochemical Equipment Tube Sheet Product Processing Case:16Mn III + ERCuNi

This case features the fabrication of a tube sheet for petrochemical heat exchange equipment. The base material, 16Mn III, offers excellent strength and weldability, while the inner surface is c [...] -

Repairing a Titanium Agitator Shaft Using Laser Cladding Technology

At FNS Pipeline Technology Co., Ltd., we are committed to delivering the most advanced surface engineering solutions to meet our customers’ highly specific and challenging requirements. Re [...] -

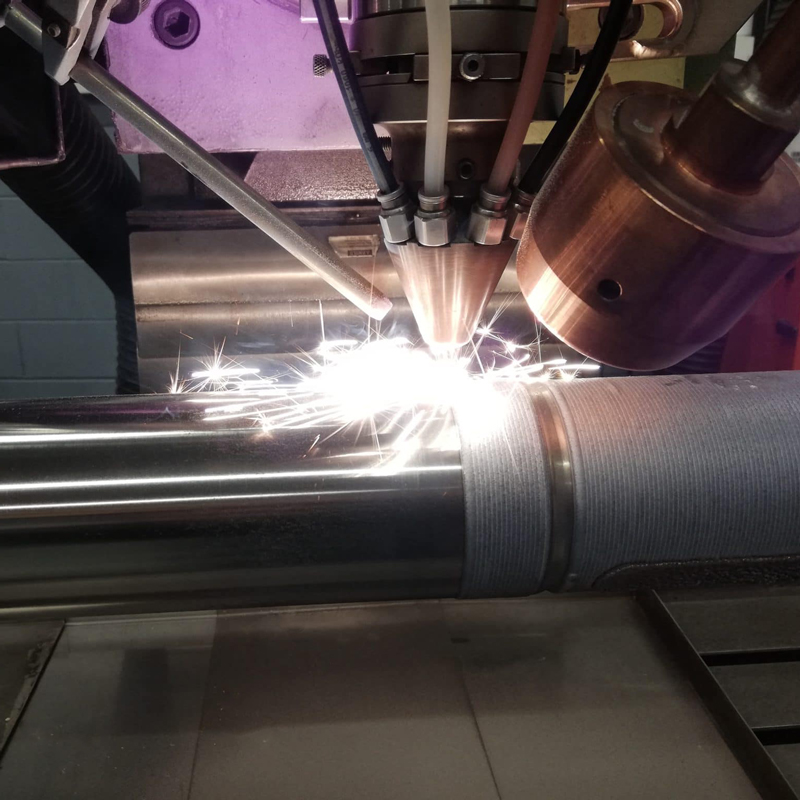

Plasma Cladding Solutions for Hydraulic Supports: Enhanced Wear Protection for Mining Equipment

Hydraulic supports are critical structural components in modern longwall mining. Their function is to maintain roof stability and ensure safe coal extraction under extreme underground conditions [...] -

Plasma Hardfacing Coating Solutions for Mining Coal Cutting Picks – Application Case Study

Mining environments expose coal cutting picks to extreme impact, abrasion, and continuous friction. To improve durability and operational safety, plasma hardfacing has become one of the most eff [...] -

Plasma Hardfacing Applications in Paper Machinery

The paper manufacturing industry relies heavily on equipment that operates under continuous friction, humidity, pressure, and chemical exposure. Key components such as press rolls, doctor blades [...] -

Laser Cladding Rotary Tiller Blades for Extended Wear Life

A laser cladding rotary tiller blade is an upgraded agricultural cutting tool designed for high-load, long-duration field operations. By applying laser cladding technology to the blade surface, [...]