Laser Cladding Repair for Die Casting Machine Barrels: A Cost-Effective Surface Restoration Solution

Die casting machine barrels operate under extreme temperature, pressure, and friction. Over time, wear, erosion, and thermal fatigue can severely reduce performance and production efficiency. Instead of replacing the entire barrel, laser cladding repair for die casting machine barrels provides a reliable and cost-effective surface restoration solution.

At FNS Pipeline Technology Co., Ltd., we specialize in advanced surface engineering technologies, offering precision laser cladding services that restore barrel geometry, enhance wear resistance, and significantly extend service life.

Why Die Casting Machine Barrels Fail

Barrels in die casting systems are constantly exposed to:

- High thermal cycling

- Molten metal erosion

- Abrasive wear from alloys and additives

- Mechanical stress under high injection pressure

These factors lead to surface cracking, dimensional wear, and reduced hardness. Without timely repair, productivity drops and the risk of sudden failure increases.

This is where laser cladding technology for barrel refurbishment becomes a superior alternative to full replacement.

What Is Laser Cladding Repair for Die Casting Machine Barrels?

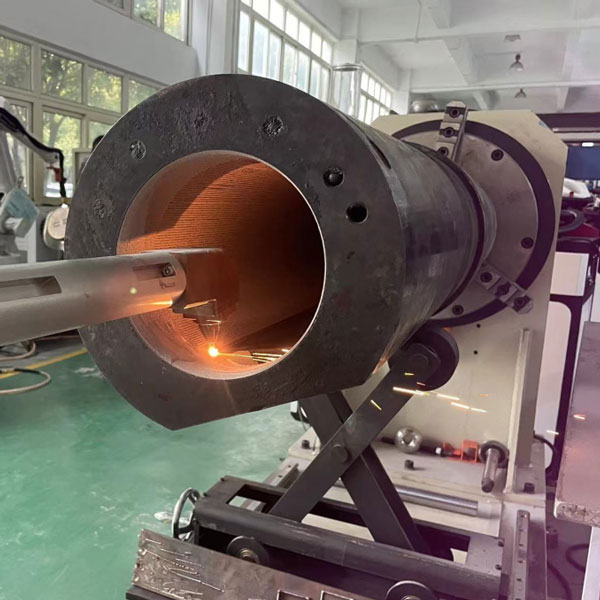

Laser cladding is an advanced surface repair process that uses a high-energy laser beam to melt metal powder or wire onto the damaged barrel surface. The coating material and base metal form a strong metallurgical bond, creating a dense, wear-resistant layer.

In laser cladding repair solution for die casting machine barrels, only the worn or damaged area is treated. This localized restoration reduces downtime and avoids the high cost of replacing the entire component.

Laser cladding repair for die casting machine barrel surface restoration

Technical Advantages of Laser Cladding Technology

1. Rapid Solidification and Fine Microstructure

With cooling rates up to 10⁶ °C/s, laser cladding produces fine grain structures and sometimes non-equilibrium phases that cannot be achieved through conventional processes. This significantly improves hardness and wear resistance.

2. Strong Metallurgical Bonding

The cladding layer and base barrel material form a metallurgical or diffusion bond. The bonding strength is comparable to the parent metal, preventing peeling or delamination.

3. Low Dilution Rate and Precise Control

Laser parameters such as power, scanning speed, and focal distance can be precisely adjusted. This allows strict control of melt depth and dilution rate—critical for precision laser cladding repair of die casting barrels.

4. Minimal Heat-Affected Zone

The heat-affected zone (HAZ) is typically between 0.1–0.5 mm. Since only the surface is melted, distortion is minimal—ideal for high-tolerance industrial components.

5. Wide Hardness Range

The cladding layer is dense and defect-free, with hardness ranging from 18–60 HRC depending on material selection. This flexibility allows custom wear-resistant laser cladding solutions for die casting barrels.

6. Flexible Material Selection

Laser cladding enables high-melting-point alloys to be deposited on lower-melting-point substrates. Metal powders, alloy blends, and ceramic-reinforced materials can be selected based on operational demands.

7. On-Site and Large Component Repair

Laser energy can be transmitted over long distances, making it suitable for on-site restoration of large industrial components.

8. Non-Contact and Handheld Flexibility

The non-contact process allows cladding in grooves and deep holes. Handheld laser cladding systems provide flexibility for complex geometries without extensive programming.

Laser Cladding Repair Process for Die Casting Machine Barrels

At FNS Pipeline Technology Co., Ltd., our industrial laser cladding repair service for die casting machine barrels follows a structured process:

Step 1: Surface Preparation

The damaged barrel surface is thoroughly cleaned to remove oxides, oil, and contaminants.

Step 2: Parameter Optimization

Laser power, beam diameter, scanning speed, and powder feed rate are determined based on barrel material and wear condition.

Step 3: Laser Cladding Application

Metal powder or wire is fed into the melt pool and fused onto the surface under controlled conditions.

Step 4: Post-Processing

After solidification, the barrel undergoes machining, grinding, or polishing to restore dimensional accuracy.

Benefits of Laser Cladding Repair Over Replacement

Choosing laser cladding repair solution for die casting machine barrels offers clear economic and technical advantages:

- Reduced replacement cost

- Extended service life

- Shorter downtime

- Improved wear and corrosion resistance

- Customized performance enhancement

Compared with alternative surface repair methods such as plasma spraying or electroplating, laser cladding provides stronger bonding, lower dilution, and superior structural integrity.

Applications Beyond Die Casting

While widely used in die casting machine barrel restoration, laser cladding is also applied in:

- Aerospace component repair

- Automotive mold restoration

- Heavy machinery surface strengthening

- Oil & gas equipment refurbishment

This versatility makes it a key surface engineering solution across industries.

Why Choose FNS Pipeline Technology Co., Ltd.?

FNS Pipeline Technology Co., Ltd. combines technical expertise with advanced laser systems to deliver:

- Precision process control

- Customized alloy powder development

- Stable metallurgical bonding

- Reliable industrial repair solutions

Our team evaluates material type, wear pattern, repair objectives, and cost efficiency before recommending the optimal laser cladding solution.

When die casting machine barrels show signs of wear, full replacement is not always necessary. Laser cladding repair for die casting machine barrels provides a technologically advanced, cost-efficient, and performance-enhancing alternative.

By restoring surface integrity and improving hardness and wear resistance, this process significantly extends operational life while maintaining dimensional accuracy.

For customized surface restoration solutions, FNS Pipeline Technology Co., Ltd. delivers precision, reliability, and long-term performance.