-

Laser Beam Welding (LBW): High-Precision Welding Solutions for Industrial Applications

In modern industrial manufacturing, achieving high-quality, precise metal joints is essential-especially in sectors such as pipelines, pressure vessels, and energy equipment. Laser Beam Welding [...]12.29.2025 -

Hardfacing Welding: Enhancing Wear Resistance and Equipment Service Life

Hardfacing is a proven surface engineering technology that improves the wear resistance, corrosion resistance, and impact strength of metal components. By depositing a protective alloy layer ont [...]12.22.2025 -

90° Long Radius Elbow with Internal Cladding

Base Material: Carbon SteelOverlay Material: Inconel 625 (NiCrMo-3) Our 90° long radius elbows with internal cladding are designed for use in highly corrosive and high-temperature e [...]04.11.2025 -

Babbitt Alloy Cladding for Large-Diameter Journal Bearings

In heavy-duty industries such as rolling mills, marine propulsion, hydroelectric plants, and large generators, journal bearings are the backbone of rotating equipment. To withstand extreme loads [...]04.10.2025 -

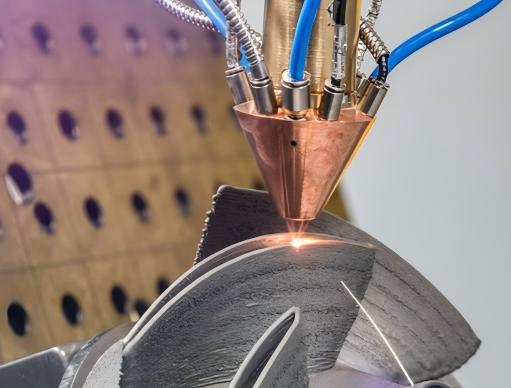

Tungsten Carbide Cladding for PDC Drill Bits

Tungsten carbide cladding offers significant advantages for PDC drill bits, enhancing their performance and lifespan in demanding drilling operations. Forming Process: Utilizing advanced automat [...]04.10.2025 -

Internal Cladding for Cross Fittings (ER316L)

Cross fittings (four-way connectors) with ER316L internal cladding are critical in pipelines transporting aggressive media. Forming Process: Using advanced automated cladding systems, a corrosio [...]04.10.2025 -

Internal Hardfacing Cladding for Pipe Fittings(Nickel-Based + Tungsten Carbide)

The combination of nickel-based alloys and tungsten carbide (WC) in hardfacing cladding creates a composite layer with exceptional wear and corrosion resistance, making it ideal for demanding in [...]04.10.2025 -

Flange Cladding Copper Alloy (nickel copper)

Copper-nickel alloys (e.g., Monel 400, 90/10 Cu-Ni) are renowned for their exceptional corrosion resistance, making them ideal for flange cladding in aggressive environments. Copper-nickel alloy [...]04.10.2025 -

Flange Cladding (ER309LMo + 316L)

Flange cladding with ER309LMo + 316L is a specialized process used in industries where flanges require enhanced corrosion resistance, high-temperature performance, and mechanical strength. This [...]04.10.2025 -

90° Long Radius Elbow Cladding

A 90° long radius elbow cladding is a process where a corrosion-resistant or wear-resistant material is applied to the inner surface of a 90-degree elbow with a long radius bend. This is typical [...]04.10.2025 -

Drilling Eight-way Cladding

Forming Process: Utilizing advanced automated cladding technology, high-performance alloy layers are applied to the inner walls of elbows, reducers, tees, crosses, end caps, valves, and other pi [...]03.26.2025 -

Tube Sheet Sealing Surface Cladding

Forming Process: Utilizing advanced automated cladding technology, high-performance alloy layers are applied to the inner wall and sealing surface of the flange. Flange Size Range: 2″-48&# [...]03.26.2025 -

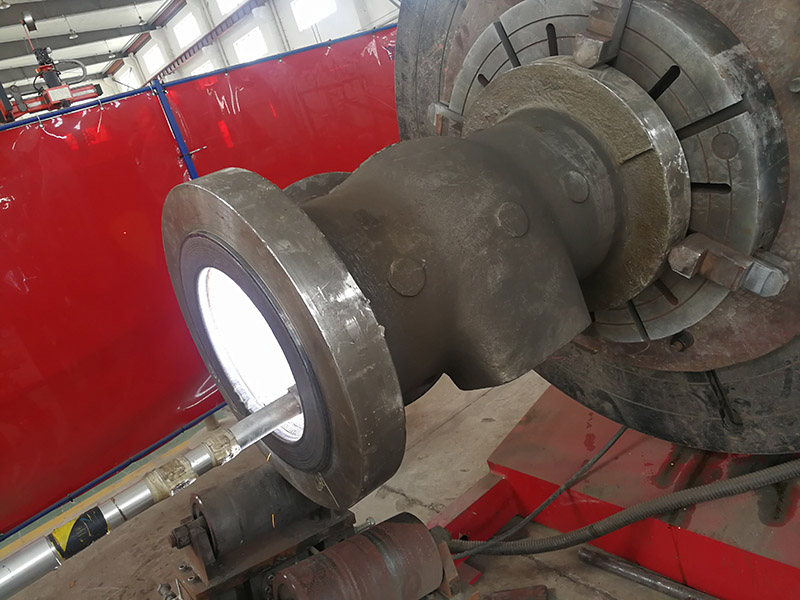

Valve Cladding

Forming Process: Utilizing advanced automated cladding technology, high-performance alloy layers are applied to the inner walls of elbows, reducers, tees, crosses, end caps, valves, and other pi [...]03.26.2025 -

CONC Reducer Cladding

Forming Process: Utilizing advanced automated cladding technology, high-performance alloy layers are applied to the inner walls of elbows, reducers, tees, crosses, end caps, valves, and other pi [...]03.26.2025 -

ECC Reducer Cladding

Forming Process: Utilizing advanced automated cladding technology, high-performance alloy layers are applied to the inner walls of elbows, reducers, tees, crosses, end caps, valves, and other pi [...]03.26.2025 -

Tee Cladding

Forming Process: Utilizing advanced automated cladding technology, high-performance alloy layers are applied to the inner walls of elbows, reducers, tees, crosses, end caps, valves, and other pi [...]03.26.2025 -

Clad Pipe Fittings

Forming Process: Utilizing advanced automated cladding technology, high-performance alloy layers are applied to the inner walls of elbows, reducers, tees, crosses, end caps, valves, and other pi [...]03.05.2025 -

Clad Pipes

In modern pipeline systems, especially those exposed to aggressive media, balancing mechanical strength with corrosion and wear resistance is a constant challenge. Clad pipes, also known as clad [...]03.05.2025 -

Clad Flanges

Clad flanges are an essential solution in industries where corrosion resistance and mechanical strength must coexist. By combining a cost-effective carbon or alloy steel base with a corrosion-re [...]03.03.2025