PRODUCT DETAILS

Clad flanges are an essential solution in industries where corrosion resistance and mechanical strength must coexist. By combining a cost-effective carbon or alloy steel base with a corrosion-resistant cladding layer such as stainless steel or nickel alloy, these flanges deliver high performance in harsh environments—while significantly reducing overall material costs.

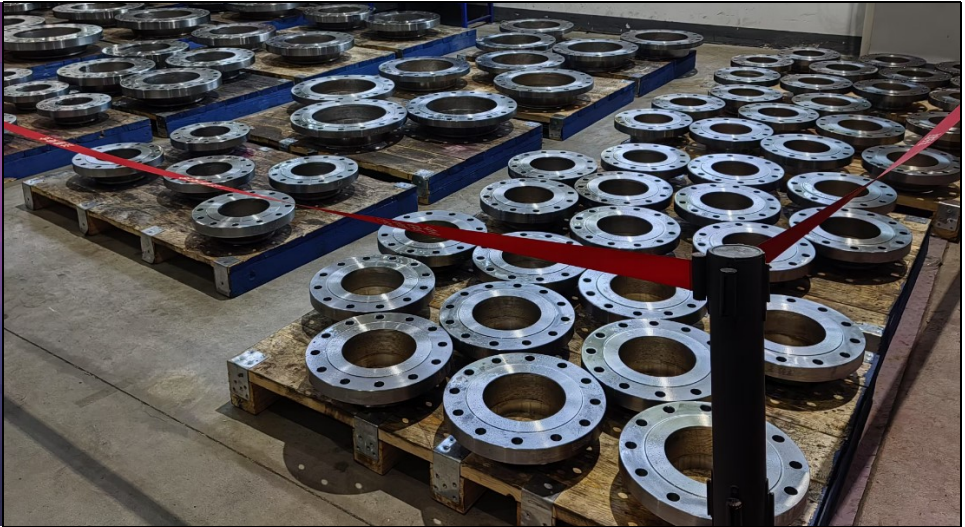

The clad flange products produced by FNS

What Are Clad Flanges?

Clad flanges are forged or welded flanges whose sealing surfaces are overlaid with a corrosion-resistant material (CRA), ensuring long-term durability and resistance to aggressive media. These flanges are widely used in oil & gas, petrochemical, power generation, offshore platforms, and chemical processing industries.

The cladding process forms a metallurgical bond between the base material and the CRA layer, ensuring excellent adhesion and consistent thickness.

Base Materials and Cladding Alloys

We offer a wide selection of base materials and corrosion-resistant overlays to meet diverse industry demands:

Base Material for Forged Flanges: Carbon steel, alloy steel, pipeline steel, stainless steel, etc.

Cladding Material: Cobalt-based alloys, nickel-based alloys, copper, stainless steel, duplex steel, titanium, and other corrosion-resistant alloys.

Common Base Materials:

- ASTM A105 (carbon steel)

- ASTM A350 LF2 (low-temp carbon steel)

- ASTM A182 F22 / F11 (alloy steels)

Typical Cladding Materials:

- Stainless steel: SS304, SS316L, SS317L

- Nickel alloys: Inconel 625, Incoloy 825, Monel 400

- Duplex and Super Duplex: UNS S31803, S32750

Each clad flange is selected based on the service medium, pressure class, temperature range, and compatibility with connected components.

CRA weld overlay flange with stainless steel cladding for corrosive environments

Manufacturing Standards & Sizes

Our clad flanges are manufactured in strict accordance with international standards including:

- ASME B16.5 (for sizes up to 24″)

- ASME B16.47 Series A & B (for sizes 26″ to 60″)

- API 6A / API 6D (for oilfield and pipeline applications)

Available Sizes:

- NPS ½” – 60″

- Pressure Ratings: Class 150 to 2500 (or equivalent PN ratings)

- Cladding Thickness: Typically 2–10 mm, customizable per client requirements

- Surface Finish: 63–125 AARH (as required by sealing standards)

Corrosion-resistant tube sheet with ER309LMo + ER316L weld overlay for heat exchanger applications

Advanced Cladding Techniques

FNS cladded flanges employ PTA, laser cladding, GTAW, and CMT advanced automated welding technologies to apply a high-performance wear-resistant and corrosion-resistant alloy layer on the inner wall or sealing surface. This process ensures interference bonding between two materials, providing high wear resistance, superior corrosion resistance, low dilution rate, strong adhesion, and uniform axial distribution.

| Process | Description | Advantages |

|---|---|---|

| GTAW (TIG) | Gas Tungsten Arc Welding | Precise, suitable for small diameters |

| PTA | Plasma Transferred Arc | High deposition rates, deep bonding |

| Laser Cladding | Low heat input, minimal dilution | Ideal for high-precision sealing surfaces |

| CMT (Cold Metal Transfer) | Low spatter, stable arc | Excellent for large-diameter flanges |

All processes are performed under strict quality control using certified equipment and skilled welders, ensuring uniform CRA thickness, minimal dilution (<10%), and reliable metallurgical bonding.

Typical Applications

Clad flanges are widely used in:

- Offshore oil and gas platforms (splash zones, subsea)

- Chemical reactors handling acidic media (H₂S, chlorides)

- Heat exchangers and pressure vessels

- Desalination plants and marine environments

- Power plants (especially for flue gas desulfurization units)

In all these applications, clad flanges provide both corrosion resistance and mechanical integrity under extreme conditions.

Magnetic particle testing of the welded flange

Quality Assurance and Testing

Each flange undergoes rigorous inspection and testing procedures before shipment:

- Positive Material Identification (PMI)

- Ultrasonic Testing (UT)

- Dye Penetrant Testing (DPT)

- Radiographic Testing (as required)

- Clad thickness measurement and dilution analysis

We also provide full documentation including MTC (EN 10204 3.1 or 3.2), welding procedures, and NDT reports.

Advantages of Using Clad Flanges

- Cost Efficiency: Reduces the use of expensive CRA materials

- Corrosion Resistance: Excellent protection against pitting, crevice, and stress corrosion

- Mechanical Strength: Retains the high tensile and pressure-bearing properties of the base material

- Weld Compatibility: Compatible with CRA piping systems without galvanic corrosion concerns

- Customization: Flexible to different dimensions, pressure classes, and special alloys

Flange surfacing equipments

Why Choose Us?

With over a decade of experience in metallurgical engineering and corrosion-resistant solutions, we deliver reliable clad flange products tailored to your project needs. Our in-house cladding capabilities, stringent QC, and global project references make us a trusted partner in critical applications. Flange welding can be carried out using CCC/ETR and horizontal equipment. Currently, the number of adjustable welding equipment exceeds 100, and the welding capacity exceeds 500 tons per year.

Get in Touch

Looking for a specific configuration or alloy combination? Contact us today to request a technical consultation or a custom quotation. We offer fast lead times, full documentation packages, and global delivery.

📧 Email: sales@chinapipings.com

Our Customers

NEXT: Clad Pipes