-

Hardfacing Alloys for Metal-Seated Valves: Technology Trends and Applications

Metal-seated valves are critical components in industrial pipeline systems. Their sealing performance directly affects operational safety, service life, and system reliability. Under high pressu [...]01.27.2026 -

Gantry-Type Dual-Torch Middle Trough Hardfacing Machine: A New Breakthrough in Welding Technology

In modern industrial manufacturing, innovation in hardfacing technology plays a decisive role in improving productivity, extending equipment life, and reducing maintenance costs. As industries d [...]01.26.2026 -

PTA-PST Technology: Advanced Tungsten Carbide Surface Hardfacing for Extreme Wear Resistance

In industries where components are exposed to severe abrasion, impact, and high operational loads, surface protection is no longer optional—it is critical. PTA-PST (Plasma Transfer Arc – Postpos [...]01.23.2026 -

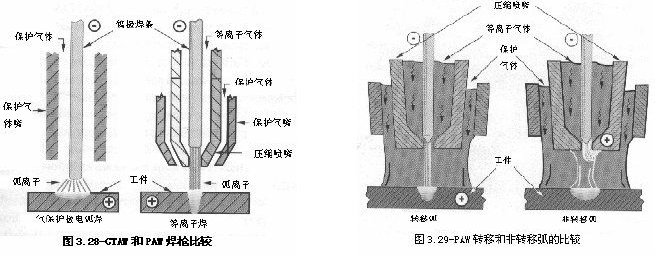

Plasma Arc Welding (PAW) vs. GTAW: Key Differences and Industrial Applications

In modern pipeline fabrication and precision component manufacturing, selecting the right welding process directly affects joint quality, productivity, and long-term performance. Plasma Arc Weld [...]01.21.2026 -

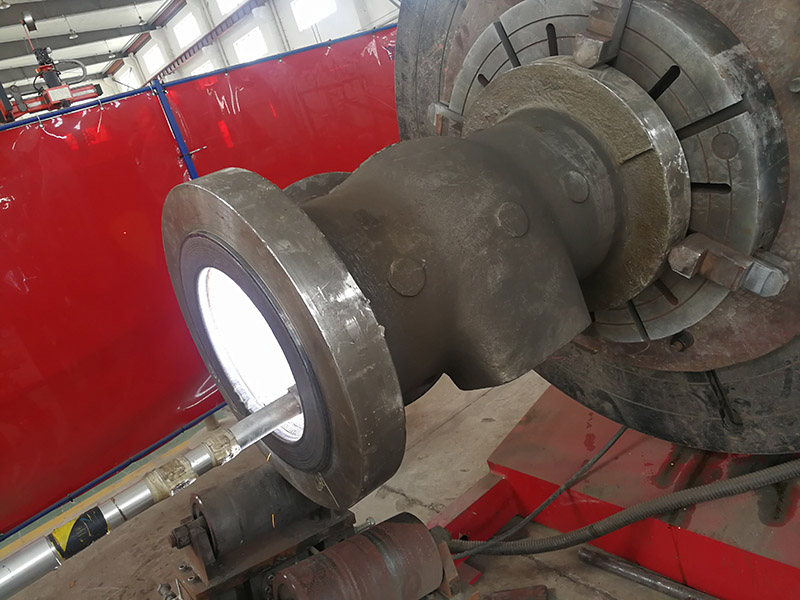

Advanced Plasma Powder Overlay Technology for Copper Blast Furnace Tuyere Durability

Blast furnace tuyeres, crucial components in high-temperature metallurgical processes, are subjected to extreme conditions, including temperatures surpassing 1500°C and intense impacts from high [...]01.19.2026 -

Plasma Arc Welding vs. TIG Welding: Process Characteristics and Industrial Advantages

Plasma Arc Welding (PAW) is an advanced welding process developed from conventional Gas Tungsten Arc Welding (GTAW or TIG). In principle, any joint that can be welded by TIG can also be complete [...]01.16.2026 -

Advanced Forms of Plasma Arc Welding and Their Industrial Applications

Plasma Arc Welding (PAW) has evolved into several advanced process variants to meet the increasing demands of precision, productivity, and material performance. Building on conventional PAW tech [...]01.15.2026 -

Causes and Prevention of Cracking in Plasma Transferred Arc (PTA) Alloy Powder Cladding

Cracking is one of the most critical quality challenges in plasma transferred arc (PTA) alloy powder cladding. If not properly controlled, cracks can compromise coating integrity, reduce service [...]01.14.2026 -

Plasma Transferred Arc Welding (PTA) Principle and Advantages for Valve Hardfacing

In demanding pipeline, petrochemical, and energy applications, valves are exposed to high pressure, corrosion, erosion, and repeated mechanical wear. To extend service life and reduce maintenanc [...]01.12.2026 -

Plasma Powder Hardfacing Technology for Drill String Stabilizers

In modern oil and gas drilling, stabilizers play a critical role in maintaining wellbore trajectory and protecting the drill string. However, under long-term all-weather and high-load horizontal [...]01.08.2026 -

Applications of Plasma Heat Treatment and Cladding Technology in Mechanical and Petrochemical Industries

In modern mechanical manufacturing and the petrochemical industry, equipment components often operate under high temperature, heavy load, corrosion, and severe wear conditions. Over time, these [...]01.07.2026 -

Stainless Steel Overlay Welding on Carbon and Low-Alloy Steels: Dilution Control and Material Selection

In industrial manufacturing and maintenance, stainless steel overlay welding on carbon steel and low-alloy steel is widely used to improve corrosion resistance, wear resistance, and service life [...]01.04.2026 -

Plasma Arc Welding (PAW): Advanced Welding Solutions Beyond TIG

Plasma Arc Welding (PAW) is an advanced welding process developed from conventional TIG (GTAW) welding. In practice, almost any joint that can be welded using TIG can also be completed with plas [...]12.31.2025 -

Laser Beam Welding (LBW): High-Precision Welding Solutions for Industrial Applications

In modern industrial manufacturing, achieving high-quality, precise metal joints is essential-especially in sectors such as pipelines, pressure vessels, and energy equipment. Laser Beam Welding [...]12.29.2025 -

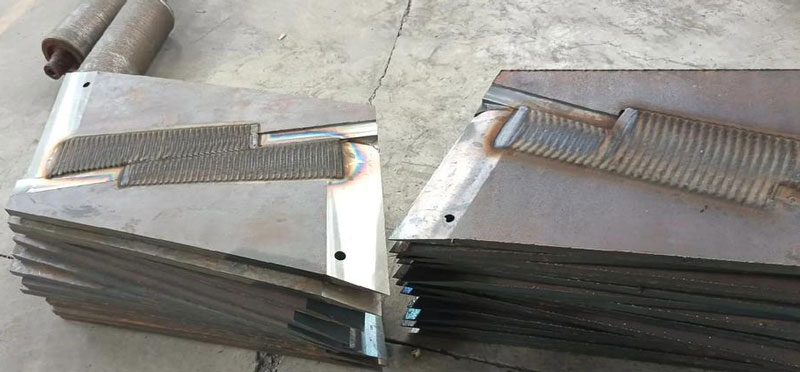

Wear-Resistant Hardfacing Solutions for Guide Plates in Industrial Applications

Guide plates are critical components widely used in boilers, metallurgical equipment, and chemical processing systems. Their primary function is to guide, support, and stabilize pipes or mechani [...]12.26.2025 -

KTIG Welding Technology: High-Efficiency and Precision Metal Joining Solutions

In modern industrial manufacturing, metal joining plays a critical role in ensuring structural integrity, productivity, and long-term reliability. While traditional welding methods such as TIG a [...]12.25.2025 -

Hardfacing Welding: Enhancing Wear Resistance and Equipment Service Life

Hardfacing is a proven surface engineering technology that improves the wear resistance, corrosion resistance, and impact strength of metal components. By depositing a protective alloy layer ont [...]12.22.2025 -

Plasma Powder Hardfacing Solution for Piercing Plugs

Piercing plugs play a critical role in the production of seamless steel pipes. Operating under extreme temperatures, heavy loads, and severe friction, they are among the most highly stressed com [...]12.18.2025 -

Valve Hardfacing Applications: Industry Challenges and Plasma Hardfacing Solutions

In industrial valve systems, the sealing surface is one of the most critical functional areas. Scratching, erosion, and corrosion are common failure modes that directly compromise sealing perfor [...]12.16.2025 -

Plasma Transferred Arc Welding (PTAW): Advanced Surface Enhancement Solutions

Plasma Transferred Arc Welding (PTAW) is an advanced hardfacing technology derived from Gas Tungsten Arc Welding (GTAW). By integrating plasma arc principles, PTAW offers superior control, highe [...]12.15.2025 -

Screw Hardfacing Repair: Extending Equipment Life and Ensuring Stable Production

In many industrial sectors, the screw is a core component responsible for material conveying, extrusion, mixing, and pressure build-up. Over long-term operation, screws endure heavy loads, abras [...]12.11.2025 -

Plasma Welding: Enhancing Wear Resistance of PDC Drill Bits

In modern oil and gas exploration, drilling efficiency depends heavily on the durability and performance of the drill bit. PDC (polycrystalline diamond compact) drill bits are widely used thanks [...]12.10.2025 -

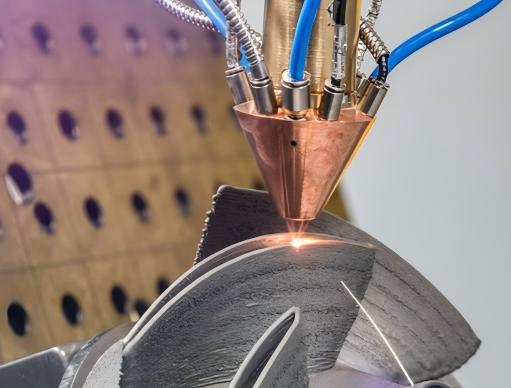

Laser Cladding Process for Manufacturing High-Speed Steel Cutting Tools

High-speed steel (HSS) cutting tools are widely used in the machining industry due to their excellent machinability and toughness. However, when machining hard materials, cutting temperatures ca [...]12.09.2025 -

How Laser Cladding Restores Wind Power Components

Wind turbine components such as main shafts, hubs, bases, gearbox housings, planet carriers, torque supports, motor shells, and wind power flanges operate under harsh loads and fluctuating envir [...]12.05.2025