Hardfacing Welding: Enhancing Wear Resistance and Equipment Service Life

Hardfacing is a proven surface engineering technology that improves the wear resistance, corrosion resistance, and impact strength of metal components. By depositing a protective alloy layer onto a base material through welding, thermal spraying, or laser processes, hardfacing significantly extends the service life of industrial equipment and mechanical parts.

At FNS Pipeline Technology Co., Ltd., we provide advanced hardfacing systems and customized process solutions to support equipment manufacturing, repair, and remanufacturing across demanding industries.

Main Hardfacing Welding Methods

Different operating conditions require different hardfacing technologies. The most commonly used methods include welding overlay, thermal spraying, and laser cladding.

1. Welding Overlay (Hardfacing Welding)

Welding overlay is the most widely applied hardfacing method. Wear-resistant materials are metallurgically bonded to the base metal using arc-based welding processes.

Common welding overlay processes include:

- Shielded Metal Arc Welding (SMAW):

Cost-effective and flexible, suitable for small-scale repairs and on-site maintenance. - Gas Metal Arc Welding (MIG/MAG/GMAW):

High deposition rate and welding speed, ideal for continuous hardfacing operations. - Gas Tungsten Arc Welding (TIG/GTAW):

Excellent control and precision, suitable for complex or high-accuracy components. - Plasma Transferred Arc Welding (PTA):

Highly precise process with low dilution, ideal for high-hardness materials and premium applications.

Typical hardfacing materials include:

- Cobalt-based alloys (e.g., Stellite)

- Nickel-based alloys (NiCrMo series)

- Iron-based alloys (high-chromium cast iron)

- Tungsten carbide composite materials

2. Thermal Spraying Hardfacing

Thermal spraying melts powder or wire feedstock using flame or plasma energy and deposits it onto the substrate to form a mechanically bonded wear-resistant coating.

Common thermal spraying technologies:

- Flame Spraying

- Atmospheric Plasma Spraying (APS)

- High Velocity Oxygen Fuel (HVOF)

Key advantages:

- Suitable for large surface areas

- Minimal heat input and distortion

- Ideal for thin-walled components

3. Laser Cladding Hardfacing

Laser cladding uses a high-energy laser beam to melt alloy powder and a thin layer of the substrate simultaneously, creating a dense metallurgical bond with precise control.

Key characteristics:

- Extremely low dilution rate

- High coating quality and consistency

- Ideal for high-value components such as molds, turbine blades, and precision parts

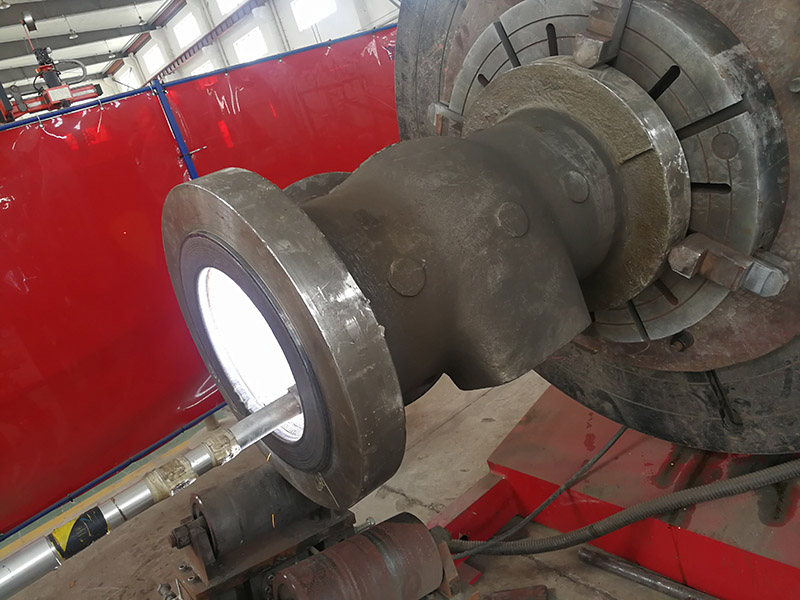

Plasma hardfacing process applied to valve sealing surface for wear and corrosion resistance

Key Advantages of Hardfacing Technology

Hardfacing delivers measurable benefits for both new equipment and remanufactured components:

- Improved wear resistance:

Extends service life in abrasive and high-load environments. - Enhanced corrosion resistance:

Suitable for chemical, marine, and high-temperature applications. - Lower maintenance costs:

Reduces replacement frequency and unplanned downtime. - Ideal for repair and remanufacturing:

Restores worn components while reducing material waste and lifecycle costs.

Typical Industrial Applications of Hardfacing

1. Mining Equipment

Challenge: Crusher hammers, bucket teeth, and liners suffer severe abrasion.

Solution: Hardfacing with high-chromium iron or tungsten carbide increases wear life by 2–5 times.

2. Oil & Gas and Petrochemical Industry

Challenge: Valve sealing surfaces experience corrosion and high temperatures.

Solution: Cobalt-based hardfacing alloys such as Stellite 6 improve corrosion resistance and sealing performance.

3. Metallurgical Equipment

Challenge: Rollers and forming tools wear quickly, affecting product quality.

Solution: Plasma Transferred Arc (PTA) hardfacing enhances wear resistance and extends service intervals.

Why Choose FNS Pipeline Technology Co., Ltd.

With extensive experience in hardfacing welding, PTA systems, laser cladding, and automated surface engineering, FNS Pipeline Technology Co., Ltd. delivers:

- Professional hardfacing equipment and power sources

- Customized wear-resistant material solutions

- Automated and robotic hardfacing systems

- Process development for repair and remanufacturing

Our solutions are designed to improve equipment reliability, reduce operating costs, and support sustainable industrial production.

Hardfacing is a critical technology for improving wear resistance, corrosion resistance, and impact strength in industrial components. As automation and intelligent welding technologies continue to evolve, hardfacing will play an increasingly important role in extending equipment life and enhancing production efficiency.

With advanced hardfacing solutions from FNS Pipeline Technology Co., Ltd., industries can achieve longer service life, lower maintenance costs, and more reliable operations.