Plasma Arc Welding vs. TIG Welding: Process Characteristics and Industrial Advantages

Plasma Arc Welding (PAW) is an advanced welding process developed from conventional Gas Tungsten Arc Welding (GTAW or TIG). In principle, any joint that can be welded by TIG can also be completed using plasma arc welding. However, due to the higher equipment cost and the relatively complex process—especially for keyhole plasma welding—the selection of PAW should always be based on specific welding conditions and performance requirements.

At FNS Pipeline Technology Co., Ltd., plasma arc welding is applied where higher penetration, better arc stability, and improved weld quality provide clear technical and economic benefits over traditional TIG welding.

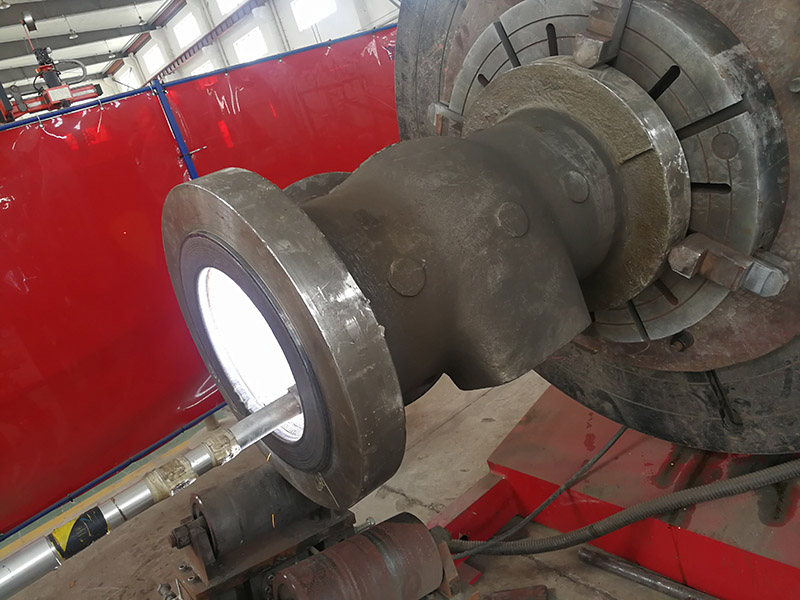

Plasma hardfacing process applied to valve sealing surface for wear and corrosion resistance

Manual and Automatic Plasma Arc Welding Modes

Similar to TIG welding, plasma arc welding can be performed in manual or automatic modes.

- Keyhole plasma welding requires automatic operation to maintain stable penetration.

- Melt-in (non-keyhole) plasma welding can be performed either manually or automatically, offering greater flexibility.

For manual melt-in plasma arc welding, the optimal current range is 0.1–50 A. When welding currents exceed 50 A, manual TIG welding is often more cost-effective. However, within the low-current range, PAW offers significant operational advantages.

Advantages of Manual Plasma Arc Welding at Low Currents

Micro plasma arc welding systems typically use a pilot arc combined with a main arc. During intermittent welding—such as multiple short weld seams or spot welds—the main arc can be extinguished while the pilot arc remains active. This allows quick and reliable re-ignition without repeated high-frequency arc starts, unlike TIG welding.

In addition, plasma arc welding is tolerant of arc length variation. An arc length deviation of ±1 mm has little impact on weld quality. This makes manual plasma arc welding particularly suitable for applications where frequent arc starts are required and precise arc length control is difficult, such as wire mesh welding.

Automatic Plasma Arc Welding for Precision Components

Automatic melt-in plasma arc welding is widely used in precision manufacturing. Micro plasma arc welding is especially suitable for small, thin, and high-accuracy components, including:

- medical device components

- optical instrument parts

- precision mechanical components

- diaphragms and bellows

Compared with TIG welding, plasma arc welding provides better arc stability and penetration control for ultra-thin materials.

Thickness Capability: Plasma Arc Welding vs. TIG Welding

TIG welding is generally suitable for materials thicker than 0.2 mm. When welding ultra-thin circumferential joints, arc starting and stopping are more difficult with TIG than with plasma arc welding.

For thicker materials, plasma arc welding offers clear advantages. Keyhole plasma arc welding can achieve full penetration in a single pass on materials with thicknesses of 1.6–8 mm, while TIG welding typically requires multiple passes once the thickness exceeds 3 mm. This allows higher welding speed and reduced heat input.

Performance on High-Melting-Point Materials

Plasma arc welding features a high arc temperature, strong arc stiffness, and highly concentrated heat input. When welding high-melting-point or heat-resistant alloys, the molten metal exhibits better fluidity, resulting in smoother bead appearance and higher welding efficiency.

In contrast, TIG welding often produces a more viscous weld pool under the same conditions, leading to slower welding speed and less visually appealing weld surfaces.

Ideal for Single-Sided Welding with Back Bead Formation

Due to its strong penetration and concentrated heat, plasma arc welding is one of the most effective arc welding processes for achieving single-sided welding with double-sided formation. Compared with TIG welding, melt-in plasma welding produces:

- a higher depth-to-width ratio

- a narrower heat-affected zone

- improved molten pool support on both sides of the joint

Keyhole plasma arc welding inherently enables back bead formation in a single pass, making it ideal for pipelines, pressure components, and precision assemblies.

FNS Expertise in Plasma Arc Welding Solutions

With extensive experience in pipeline fabrication, precision welding, and automated welding systems, FNS Pipeline Technology Co., Ltd. helps customers select the most suitable welding process—whether TIG or plasma arc welding—based on material thickness, joint design, productivity targets, and cost efficiency.