-

Application of Laser-Arc Hybrid Welding in the Oil & Gas Pipeline Industry

Laser-arc hybrid welding is a next-generation welding technology that combines the strengths of laser welding and arc welding into a single, highly versatile process. By allowing both heat sourc [...]11.25.2025 -

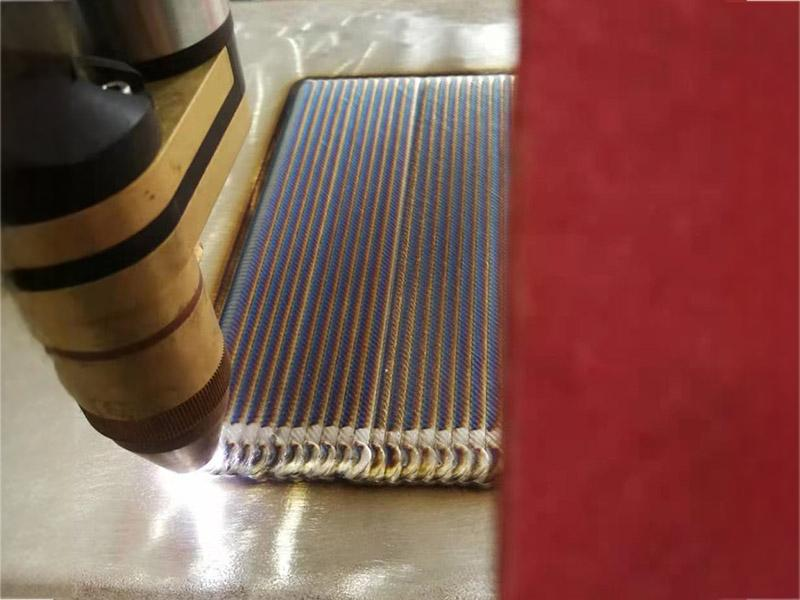

Optical Lens Requirements Inside a Laser Cladding Head

Laser cladding is a high-energy manufacturing process in which alloy powders are melted by a concentrated laser beam to form metallurgically bonded coatings or 3D structures on a substrate. In a [...]11.24.2025 -

Composition and Applications of Babbitt Alloy

Babbitt alloy, also known as Babbitt metal, is a low-melting, soft bearing alloy widely used as the working surface of sliding bearings. Composed primarily of tin, lead, antimony, and copper, th [...]11.19.2025 -

Amorphous Materials and Their Application in Laser Cladding Technology

Amorphous materials—also known as metallic glass—represent a class of solid metallic materials in which atoms lack long-range order. This unique amorphous structure gives rise to exceptional mec [...]11.18.2025 -

Classification and Applications of Cemented Carbide

Cemented carbide is widely recognized for its exceptional hardness, wear resistance, and performance under demanding operating conditions. At FNS Pipeline Technology Co., Ltd., we work with vari [...]11.17.2025 -

The Manufacturing Process of Cemented Carbide: Powder Metallurgy Explained

The manufacturing process of cemented carbide is the foundation of one of the most durable and wear-resistant materials used in modern industry. At FNS Pipeline Technology Co., Ltd., this materi [...]11.14.2025 -

The Key Properties and Applications of Cemented Carbide in Industrial and Pipeline Engineering

Cemented carbide, also known as tungsten carbide or hard metal, is a high-performance wear-resistant material widely used in modern manufacturing, mining, and pipeline engineering. It is produce [...]11.13.2025 -

Understanding the Composition of Metal Matrix Composites (MMCs)

Metal Matrix Composites (MMCs) represent a new generation of high-performance materials that combine the toughness of metals with the strength and stiffness of reinforcement phases. By integrati [...]11.12.2025 -

Coated Cemented Carbides: Enhancing Tool Performance with Advanced Surface Technology

Coated cemented carbides have become a cornerstone of modern cutting tool technology. By applying an ultra-hard coating layer onto a cemented carbide substrate, these tools achieve a balance of [...]11.07.2025 -

Why Cladding Layers Fail to Bond Properly or Peel Off — Causes and Solutions

In modern industrial repair and surface enhancement, cladding plays a crucial role in restoring worn or damaged parts. However, when the cladding layer fails to bond properly with the base metal [...]11.06.2025 -

All-in-One Welding Solution: iWave Platform Upgrade Delivers Multi-Process Integration

FNS Pipeline Technology Co., Ltd. has introduced a major upgrade to its iWave platform, expanding its capabilities with a full suite of advanced welding processes. Designed for high-demand autom [...]11.05.2025 -

ADIPEC 2025 Live: Surface Integrity Takes Center Stage! FNS Drives Corrosion Solution Consultations at Stand 13880

FNS (Nanjing) Surface Engineering Service Co., Ltd. is proud to report an extremely high-impact opening day at ADIPEC 2025! The FNS team, the surface technology expert in our collaboration, welc [...]11.03.2025 -

FNS (Nanjing) Brings Cutting-Edge Surface Engineering to ADIPEC 2025

FNS (Nanjing) Surface Engineering Service Co., Ltd., a specialist in industrial coating, corrosion protection, and surface modification technologies, is proud to announce its participation in AD [...]10.21.2025 -

Metal Matrix Composites: Structure, Advantages, and Industrial Applications

In modern engineering, the demand for materials that combine strength, lightness, and durability has driven the development of Metal Matrix Composites (MMCs). By integrating a metallic base with [...]10.17.2025 -

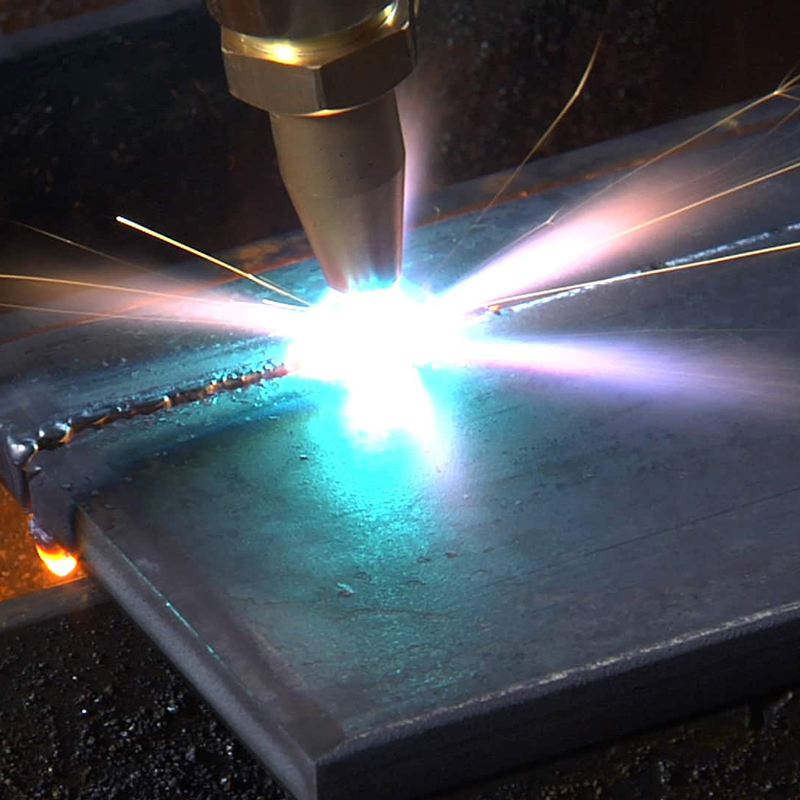

LaserHybrid Welding: Unlocking the Future of High-Efficiency Metal Joining

For decades, laser welding and MIG/MAG welding have been the cornerstones of modern fabrication. But what happens when you combine the precision of a laser with the adaptability of an electric a [...]10.13.2025 -

Stainless Steel Pipe vs Coated Pipe vs Clad Pipe: How to Choose the Right Solution

In industries such as oil & gas, petrochemical, power generation, and water treatment, selecting the right pipeline material is critical for safety, reliability, and cost efficiency. Corrosi [...]09.25.2025 -

How Corrosion Resistant Pipes Are Manufactured and Protected

Corrosion is one of the most critical challenges in pipeline engineering. Whether in the oil & gas industry, petrochemical plants, or power generation facilities, the degradation of steel ca [...]09.25.2025 -

Fe10W, Fe10V, and Fe6V Alloy Powders: Optimized Cladding Solutions for Demanding Industries

In industries such as mining, oil & gas, and heavy machinery, component wear is a constant challenge that reduces efficiency and increases maintenance costs. To extend service life and impro [...]09.23.2025 -

Fe10W Alloy Powder for Cladding | Cost-Effective Wear Protection | FNS

In today’s industrial environment, rising material costs—particularly for tungsten carbide (WC) products—pose significant challenges for industries that rely on wear-resistant components. [...]09.18.2025 -

10V Alloy Steel Powder for Cladding: The “King of Wear Resistance” with Stable 62HRC Hardness

In modern industry, equipment wear remains one of the main causes of reduced productivity and shortened service life. 10V alloy steel powder for cladding, developed with advanced metallurgy and [...]09.10.2025 -

Thermal Spraying vs. Spray Welding vs. Overlay Welding: Differences and Connections

In the field of surface engineering and component repair, three widely used technologies—thermal spraying, spray welding, and overlay welding—play a key role in extending service life and enhanc [...]09.08.2025 -

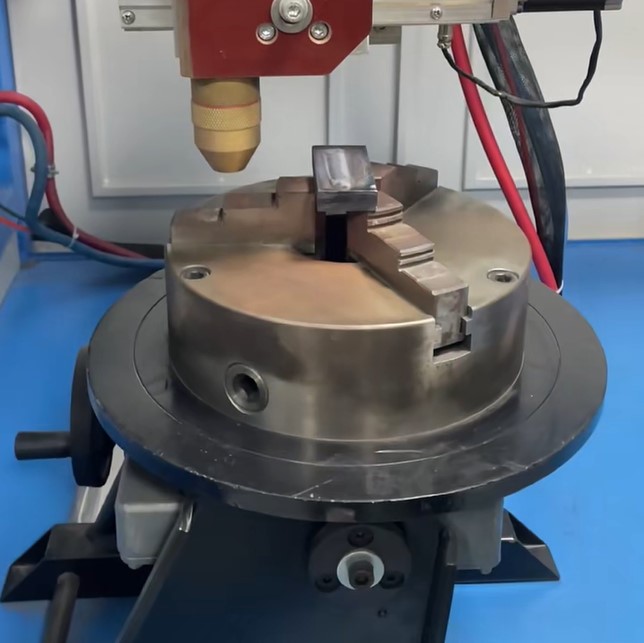

Differences and Selection Between Oxy-Acetylene spray welding and Plasma Cladding

In modern surface engineering technology, both Oxy-Acetylene spray welding and plasma cladding play vital roles across industries such as machinery manufacturing, petrochemicals, and aerospace. [...]09.04.2025 -

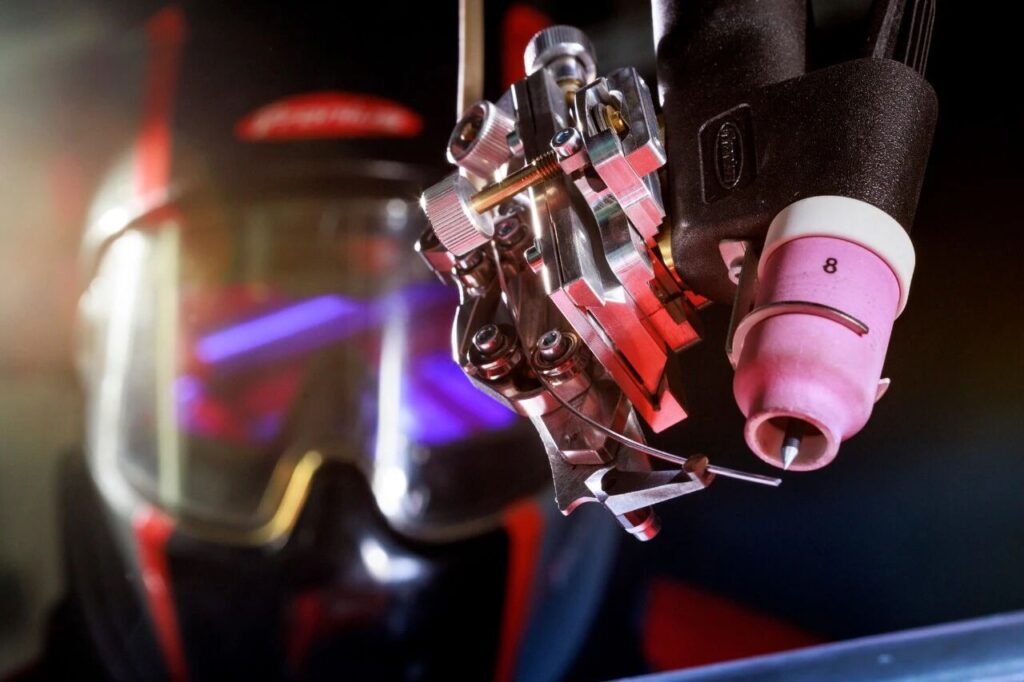

FNS iWave Welding Platform – TIG DynamicWire, Multiprocess PRO & CMT Additive Innovations

FNS Pipeline Technology Co., Ltd. proudly introduces the iWave Welding Platform, an intelligent all-in-one system designed for automated applications. Following the successful launch of the manu [...]09.03.2025 -

Pulse Welding as a Universal Solution for Steel Welding

In the world of welding, it is tempting to search for a universal process that suits every material and application. While no such perfect solution exists, one approach stands out in the field o [...]09.01.2025