The Manufacturing Process of Cemented Carbide: Powder Metallurgy Explained

The manufacturing process of cemented carbide is the foundation of one of the most durable and wear-resistant materials used in modern industry. At FNS Pipeline Technology Co., Ltd., this material plays a central role in producing reliable components for oil & gas pipelines, flow-control systems, drilling tools, and high-abrasion industrial equipment.

Cemented carbide—also called tungsten carbide—is an engineered composite consisting of extremely hard WC particles bonded with metallic cobalt. Its performance depends entirely on a precise powder metallurgy process, where every stage determines hardness, toughness, and service life.

1. Powder Synthesis: Producing High-Purity Raw Materials

The manufacturing of cemented carbide begins with the production of tungsten carbide (WC) powder. High-purity tungsten powder reacts with carbon black at 1500–2000°C in a hydrogen atmosphere to form WC particles.

At the same time, cobalt powder is prepared to serve as the metallic binder. Its purity and particle size are crucial, as cobalt distribution significantly affects hardness, toughness, and wear resistance—key factors for wear-resistant pipeline components.

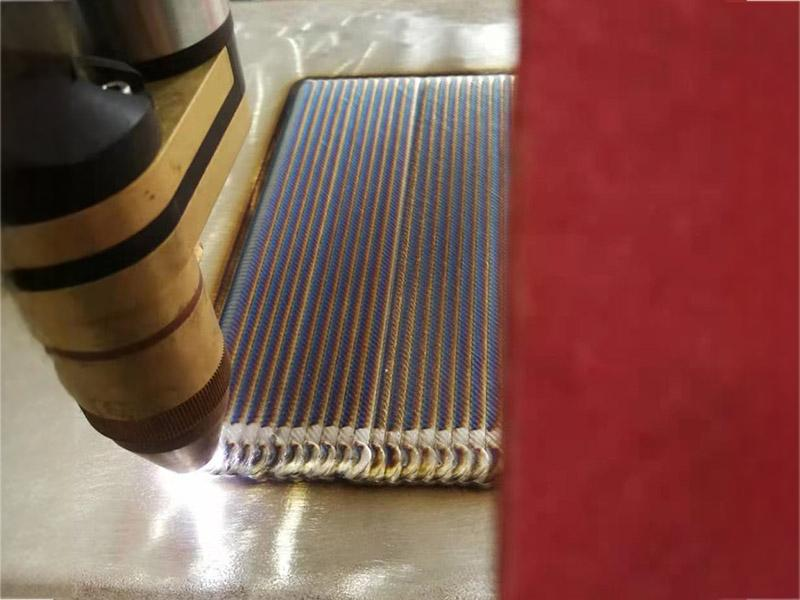

Tungsten Carbide Cladding

2. Mixing and Mechanical Alloying

WC and Co powders are precisely measured and blended to achieve a targeted composition. Inside a ball mill, the powders undergo mechanical alloying, ensuring uniform mixing and particle refinement.

A small amount of temporary binder—often paraffin—is added to improve the strength of the green compact during forming. Homogeneous distribution at this stage is fundamental for producing reliable tungsten carbide components used in valves, sleeves, and high-abrasion pipeline fittings.

3. Forming: Creating the Green Compact

The mixed powder is shaped through:

- uniaxial pressing,

- extrusion, or

- cold isostatic pressing (CIP).

These forming techniques give the product its initial geometry and density, producing what is known as a green compact. The precision of this step ensures dimensional stability during the later sintering stage and is essential for complex components used in pipeline flow control and wear-resistant assemblies.

4. Sintering: Achieving Full Density and Microstructural Uniformity

Sintering is the most critical stage of cemented carbide manufacturing. Green compacts are heated in vacuum or hydrogen protection, undergoing three main stages:

a. Debinding

The temporary binder is removed without damaging the compact.

b. Solid-State Sintering

WC particles rearrange and bond at elevated temperatures.

c. Liquid-Phase Sintering

When temperatures exceed the cobalt melting point (around 1400°C), liquid Co forms and wets WC particles.

This triggers dissolution-reprecipitation, allowing particles to densify, grow, and pack tightly. The result is a near-fully-dense microstructure with:

- extremely high hardness

- strong bonding between WC and Co

- excellent wear and corrosion resistance

These properties make sintered tungsten carbide indispensable for pipeline wear solutions, drilling tools, and high-pressure sealing components produced by FNS.

Why Powder Metallurgy Matters for Performance

The precision of powder metallurgy allows engineers to tailor:

- Cobalt content – balancing hardness and toughness

- WC grain size – controlling wear resistance

- Binder distribution – optimizing strength and durability

This level of microstructural control ensures FNS can deliver custom-engineered cemented carbide parts designed for long-term performance in harsh abrasive environments such as oil & gas pipelines, chemical plants, and mining operations.

The manufacturing process of cemented carbide is a sophisticated and highly controlled sequence of powder synthesis, mixing, forming, and sintering. Through precise microstructural engineering, FNS Pipeline Technology Co., Ltd. produces durable tungsten carbide components that withstand abrasion, corrosion, high pressure, and extreme heat.

For industries requiring dependable, long-lasting performance—from oil & gas to chemical processing and mining—cemented carbide remains the material of choice. And at FNS, we ensure every component meets the highest standards of reliability and efficiency.

Related Articles:

Coated Cemented Carbides: Enhancing Tool Performance with Advanced Surface Technology

The Key Properties and Applications of Cemented Carbide in Industrial and Pipeline Engineering