Valve Hardfacing Applications: Industry Challenges and Plasma Hardfacing Solutions

In industrial valve systems, the sealing surface is one of the most critical functional areas. Scratching, erosion, and corrosion are common failure modes that directly compromise sealing performance and service life. These issues are influenced by multiple factors, including sealing pair materials, metallurgical structure, surface treatment processes, hardness matching, contact pressure, and surface conformity.

Because each valve operates under specific temperature, pressure, and media conditions, sealing surface materials must be carefully selected to match real operating environments. At FNS Pipeline Technology Co., Ltd., valve hardfacing is widely used to enhance sealing performance while extending valve lifespan and reducing lifecycle costs.

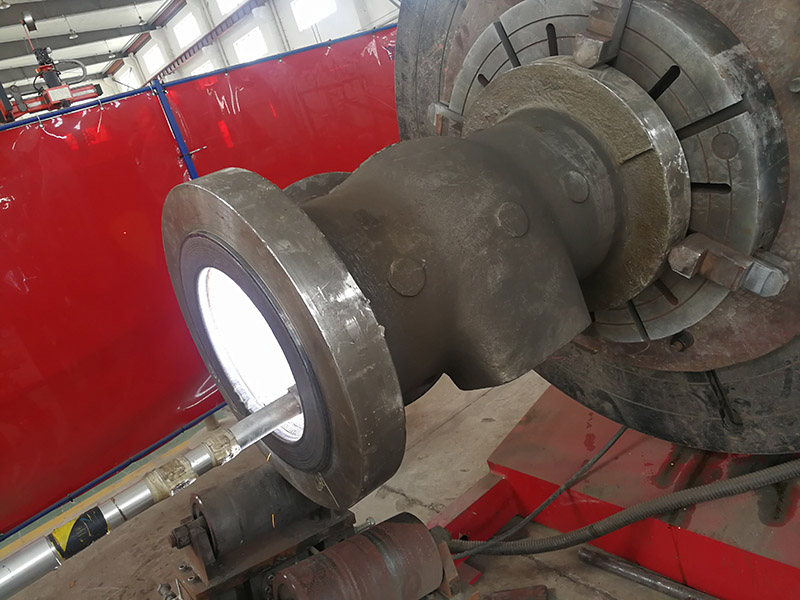

Plasma hardfacing process applied to valve sealing surface for wear and corrosion resistance

Why Valve Sealing Surfaces Fail

Hard-seated valves experience repeated friction during opening and closing cycles. Over time, this mechanical interaction leads to:

- Abrasive wear

- Galling and surface scratching

- Erosive damage from high-velocity media

- Chemical and electrochemical corrosion

These mechanisms gradually degrade the sealing surface, resulting in leakage, reduced efficiency, and unplanned downtime. Applying a wear-resistant hardfacing layer directly to the sealing surface is one of the most effective ways to mitigate these failures.

Valve Remanufacturing Through Hardfacing

For steel valves, sealing surfaces are commonly manufactured or restored using hardfacing welding techniques. Based on alloy composition, valve hardfacing materials are generally divided into four categories:

- Cobalt-based alloys

- Nickel-based alloys

- Iron-based alloys

- Copper-based alloys

These materials can be supplied as welding electrodes, solid or flux-cored wires, fluxes, or alloy powders. Various welding methods are available, including manual arc welding, oxy-acetylene welding, TIG welding, submerged arc welding, and plasma arc welding.

Among these options, plasma hardfacing has become a preferred solution for high-performance valve applications.

Advantages of Plasma Hardfacing for Valves

Plasma hardfacing uses a plasma arc as the heat source and alloy powder as the filler material. Compared with conventional hardfacing processes, it offers several clear advantages:

- High deposition efficiency, enabling faster production rates

- Controllable penetration depth with a consistently low dilution rate

- Smooth and dense overlays, with single-pass thicknesses from 0.5 to 5 mm

- Stable process control, producing defect-free layers without porosity or inclusions

- Wide material selection, including cobalt-, nickel-, iron-, and copper-based powders that can be customized for specific service conditions

- High automation potential, compatible with dedicated machines and robotic systems to reduce labor intensity

At FNS Pipeline Technology, plasma hardfacing is engineered to deliver consistent sealing quality and long-term reliability for industrial valves.

Common Misconceptions in Valve Hardfacing Material Selection

Myth 1: Higher hardness always means better wear resistance

In reality, wear resistance depends primarily on microstructural design, not hardness alone. Some alloys with an austenitic matrix and finely distributed hard phases may exhibit excellent wear resistance at moderate hardness levels. For most valve sealing surfaces, a hardness range of HRC 35–45 provides an optimal balance between wear resistance and damage tolerance.

Myth 2: Higher-priced alloys always perform better

Material cost reflects market value, not necessarily suitability. For example, cobalt-based alloys are expensive due to raw material sourcing but excel mainly in high-temperature wear applications. In ambient or medium-temperature conditions, more cost-effective alloys often deliver a better performance-to-cost ratio. Material selection should always be application-driven.

Myth 3: Corrosion resistance in one medium guarantees resistance in others

Corrosion behavior is highly sensitive to temperature, concentration, and chemical composition of the media. An alloy that performs well in one corrosive environment may fail under slightly different conditions. Reliable material selection must be based on testing data and well-defined service parameters, not assumptions or generalized references.

Why Choose FNS Pipeline Technology

With extensive experience in valve remanufacturing and surface engineering, FNS Pipeline Technology Co., Ltd. provides customized plasma hardfacing solutions that:

- Restore and enhance valve sealing performance

- Extend service life under demanding operating conditions

- Reduce replacement and maintenance costs

- Support automated, repeatable production

Our engineering-driven approach ensures that every valve hardfacing solution is optimized for real-world performance, not just theoretical material properties.

Valve hardfacing is not simply a repair process—it is a strategic upgrade to valve performance. By applying the right alloy with the right plasma hardfacing process, sealing surfaces can achieve superior resistance to wear, corrosion, erosion, and high-temperature damage.

For reliable, cost-effective valve remanufacturing, plasma hardfacing from FNS Pipeline Technology offers a proven and industrially scalable solution.