Plasma Arc Welding (PAW) vs. GTAW: Key Differences and Industrial Applications

In modern pipeline fabrication and precision component manufacturing, selecting the right welding process directly affects joint quality, productivity, and long-term performance. Plasma Arc Welding (PAW) and Gas Tungsten Arc Welding (GTAW) are closely related processes, yet they differ significantly in arc characteristics, heat control, and application scope.

At FNS Pipeline Technology Co., Ltd., both PAW and GTAW are applied based on specific project requirements, ensuring reliable weld integrity for pipelines, pressure components, and high-performance industrial parts.

Understanding the Core Difference Between PAW and GTAW

Plasma is an ionized gas that exists in all arc welding processes. However, PAW is distinguished by the intensity and control of its plasma arc.

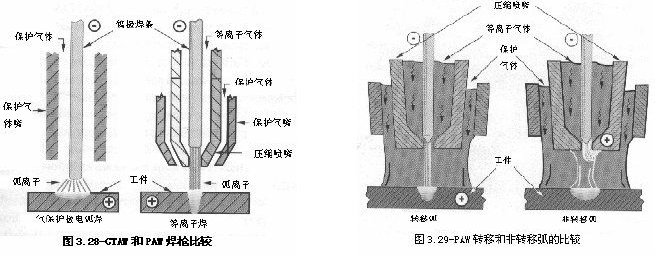

While PAW may appear similar to GTAW at first glance—since both use a tungsten electrode and comparable power sources—the welding torch design reveals the key difference. In PAW, the tungsten electrode is recessed inside a ceramic nozzle containing a water-cooled copper orifice. Plasma gas is forced through this narrow orifice, compressing the arc and creating a highly focused, high-energy heat source.

Comparison of GTAW and PAW

A simple comparison often used in industry is this:

- GTAW resembles a gentle mist, spreading heat more broadly.

- PAW behaves like a powerful, concentrated jet of steam, delivering energy precisely where it is needed.

Arc Types in Plasma Arc Welding

PAW operates using two distinct arc modes:

- Transferred Arc:

The arc forms between the tungsten electrode and the workpiece. This mode delivers high heat directly into the base material and is ideal for materials with good thermal conductivity, such as stainless steel and alloy steels commonly used in pipeline systems. - Non-Transferred Arc:

The arc is established between the tungsten electrode and the copper nozzle. This mode limits heat input to the workpiece and is more suitable for cutting or processing materials with lower thermal conductivity.

FNS engineers select the appropriate arc type to balance penetration, weld stability, and material behavior.

Equipment and Gas Requirements

Compared with GTAW, PAW requires additional equipment, including a plasma control console and a dedicated plasma gas supply. Two separate gases are used:

- Shielding gas to protect the molten weld pool

- Plasma gas (orifice gas) to form and stabilize the compressed arc

Argon is the most commonly used gas for both functions, although helium or argon-hydrogen mixtures may be applied for specific metals and thicknesses.

Penetration, Speed, and the Keyhole Effect

One of the most valuable advantages of plasma arc welding is the keyhole welding effect. When welding square-butt joints without a root gap, the concentrated arc penetrates completely through the material thickness, forming a stable keyhole. As the torch advances, molten metal flows behind the arc and solidifies into a fully penetrated weld.

Compared with GTAW, this offers several benefits:

- Full penetration in materials up to 1/2 inch (≈12 mm) in a single pass

- Higher welding speeds

- Narrower heat-affected zones (HAZ)

- Reduced distortion and improved dimensional control

For pipeline components and precision assemblies produced by FNS Pipeline Technology Co., Ltd., these advantages translate into higher consistency and lower rework rates.

Visibility, Control, and Weld Quality

Because the tungsten electrode is recessed inside the PAW torch, operators maintain a greater torch-to-workpiece distance, improving visibility and reducing the risk of tungsten contamination. PAW is also less sensitive to arc length variations, allowing stable penetration even when slight changes in torch positioning occur.

This arc stability makes PAW especially suitable for applications where consistent weld quality is critical, such as:

- Precision pipeline fittings

- Instrumentation components

- High-performance industrial assemblies

Limitations and Skill Requirements

Despite its advantages, PAW is not a universal replacement for GTAW. Equipment costs are higher, and setup is more complex. Operator skill requirements are also greater, particularly when using the keyhole welding mode.

Potential defects—such as tungsten inclusions, copper contamination from the orifice, or keyhole collapse at the weld termination—must be carefully managed through parameter control and operator experience. For this reason, FNS applies PAW selectively, where its technical advantages clearly outweigh its complexity.

PAW vs. GTAW at FNS Pipeline Technology Co., Ltd.

At FNS, GTAW remains an economical and flexible choice for thin sections and general fabrication, while PAW is used where deep penetration, high precision, and superior weld consistency are required. By integrating both processes into its manufacturing capabilities, FNS ensures optimized welding solutions for demanding pipeline and industrial projects worldwide.