Wear-Resistant Hardfacing Solutions for Guide Plates in Industrial Applications

Guide plates are critical components widely used in boilers, metallurgical equipment, and chemical processing systems. Their primary function is to guide, support, and stabilize pipes or mechanical components during operation. However, under long-term exposure to friction, impact, and corrosive environments, guide plate surfaces often suffer severe wear, significantly reducing service life and operational stability.

To address this challenge, wear-resistant hardfacing (overlay welding) technology has become an effective and proven solution for guide plate manufacturing and maintenance.

At FNS Pipeline Technology Co., Ltd., advanced hardfacing solutions are applied to enhance guide plate performance, helping customers extend equipment life and reduce maintenance costs.

Why Use Wear-Resistant Hardfacing for Guide Plates?

Wear-resistant hardfacing improves surface properties by depositing a layer of high-performance wear-resistant alloy onto the guide plate surface. This reinforced layer significantly enhances resistance to abrasion, erosion, and moderate corrosion, making guide plates more reliable under harsh operating conditions.

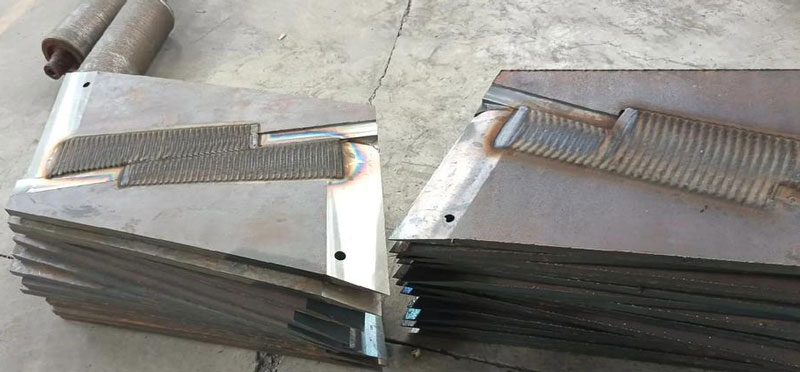

Wear-resistant hardfacing applied to industrial guide plates by FNS Pipeline Technology Co., Ltd

Hardfacing Process for Guide Plates

The wear-resistant hardfacing process is efficient and well-controlled, typically involving the following steps:

1. Surface Preparation

The guide plate surface is thoroughly cleaned, degreased, and ground to remove contaminants and ensure optimal bonding between the base metal and overlay material.

2. Preheating

Preheating is applied to reduce cooling rates and minimize welding residual stress, helping prevent cracking and deformation.

3. Hardfacing Overlay Welding

Using specialized welding electrodes, wires, or plasma welding torches, a wear-resistant alloy layer is deposited onto the guide plate surface. The alloy composition is selected based on operating conditions such as temperature, load, and wear mechanism.

4. Post-Weld Treatment

After hardfacing, the guide plate undergoes controlled cooling, surface cleaning, and precision machining if required, ensuring dimensional accuracy and surface quality.

Key Advantages of Hardfacing Reinforcement

- Material flexibility: Different wear-resistant alloys can be selected to match specific operating conditions across various industries.

- Precise process control: Welding parameters are carefully managed to limit heat input, maintaining dimensional stability and minimizing distortion.

- On-site application: Hardfacing can be performed directly at the job site, eliminating the need for factory returns and reducing downtime and logistics costs.

- Extended service life: Properly applied hardfacing can significantly increase guide plate lifespan and reduce replacement frequency.

Important Considerations

While wear-resistant hardfacing greatly improves surface performance, it does not eliminate internal defects or structural issues within the guide plate. Before applying hardfacing reinforcement, a comprehensive inspection and assessment should be conducted to determine whether additional repairs or component replacement are necessary.

Wear-resistant hardfacing technology is a highly effective solution for guide plate maintenance and performance enhancement. By improving surface durability and resistance to wear, it helps extend service life, improve operational stability, and reduce maintenance costs.

As welding and surface engineering technologies continue to advance, FNS Pipeline Technology Co., Ltd. remains committed to providing reliable, application-specific hardfacing solutions for industrial customers worldwide.