Plasma Hardfacing Repair for Bearing Seats

In heavy industrial equipment, bearing seats are among the most vulnerable areas subject to wear, corrosion, and mechanical damage. Once a bearing seat is worn or out of tolerance, the entire assembly may suffer from vibration, misalignment, or premature failure. Plasma hardfacing repair for bearing seats offers a proven and economical alternative to component replacement.

At FNS Pipeline Technology Co., Ltd., we apply advanced plasma transferred arc (PTA) hardfacing technology to restore damaged bearing seats, helping customers extend equipment life while significantly reducing maintenance costs.

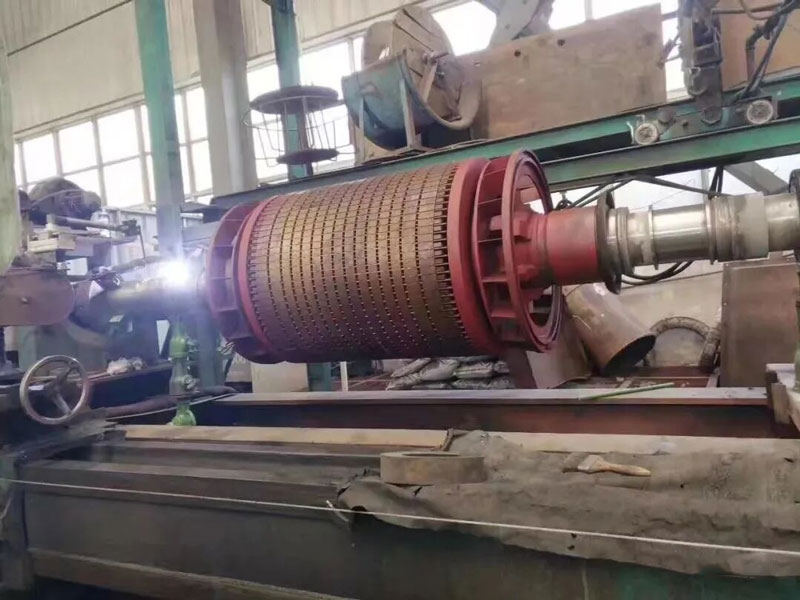

Bearing seat rebuilt using plasma transferred arc hardfacing technology

What Is Plasma Hardfacing Repair for Bearing Seats?

Plasma hardfacing repair is a precision surface restoration process. It uses a high-energy plasma arc to melt alloy filler material and metallurgically bond it to worn bearing locations. After deposition, the repaired area is machined back to its original dimensions, restoring both geometry and mechanical performance.

Compared with replacing shafts or housings, plasma hardfacing bearing repair delivers reliable results with lower material waste, shorter downtime, and excellent durability.

Plasma Hardfacing Repair Process

To ensure consistent quality, the bearing seat repair process follows several critical steps:

- Surface Preparation

The worn bearing area is thoroughly cleaned to remove grease, oxidation, and debris. Proper surface preparation ensures strong metallurgical bonding and prevents internal defects. - Plasma Hardfacing Deposition

Using a controlled plasma arc, alloy powder is deposited evenly onto the damaged bearing seat. Heat input and dilution are carefully managed to protect the base material. - Precision Machining

After hardfacing, the rebuilt bearing seat is machined to the required tolerance, ensuring perfect bearing fit and alignment.

Alloy Selection for Bearing Seat Repair

Material selection plays a decisive role in bearing performance and service life. For most applications, nickel-based and cobalt-based alloys are preferred due to their excellent wear resistance, corrosion resistance, and load-bearing capacity.

FNS Pipeline Technology selects alloy systems based on operating conditions such as load, speed, temperature, and exposure to corrosive environments, ensuring optimal performance after repair.

Key Advantages of Plasma Hardfacing Bearing Repair

- Cost-effective alternative to replacement

Restores worn bearing seats without replacing entire shafts or housings. - High precision and repeatability

Ideal for critical rotating components requiring tight tolerances. - Excellent wear and corrosion resistance

Extends bearing life in harsh industrial environments. - Minimal downtime

Fast turnaround reduces production interruptions.

Expertise Matters

Plasma hardfacing is a highly technical process. Skilled operators with deep knowledge of plasma arc behavior, metallurgy, and process control are essential. At FNS Pipeline Technology, our experienced technicians ensure every bearing seat repair meets strict quality and performance standards.

Applications of Plasma Hardfacing Bearing Repair

- Industrial pumps and compressors

- Gearboxes and drive shafts

- Heavy-duty rollers and rotating equipment

- Pipeline-related machinery and auxiliary systems

Why Choose FNS Pipeline Technology?

With extensive experience in plasma hardfacing repair for industrial components, FNS Pipeline Technology Co., Ltd. provides reliable, engineered solutions tailored to real operating conditions. Our focus on quality, process control, and long-term performance helps customers maximize equipment availability and reduce lifecycle costs.