Plasma Transferred Arc Welding (PTA): Definition, Advantages, and Applications

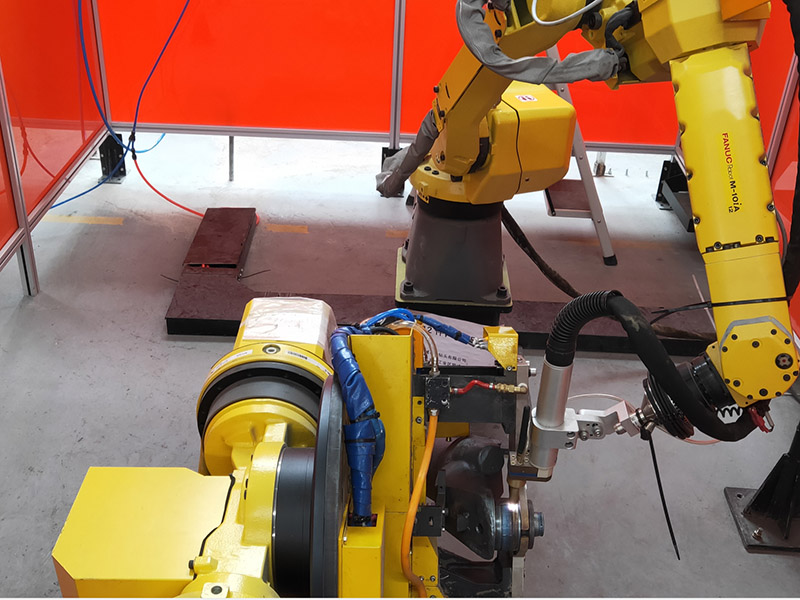

Plasma Transferred Arc Welding (PTA) is an advanced surface engineering process that uses a high-temperature plasma arc, generated by ionized argon, as its heat source. Alloy powders are precisely fed into the arc zone through a powder feeder and deposited onto the base material, creating a high-performance metallurgical coating.

Plasma transferred arc welding (PTA) cladding technology is widely applied to enhance the wear resistance, corrosion resistance, heat resistance, impact resistance, and high-temperature performance of high-value metal components. Its applications span industries such as construction machinery, mining equipment, energy, aerospace, and petrochemicals.

Plasma Transferred Arc (PTA) cladding

Key Advantages of PTA Technology

1.High Bonding Strength

PTA (Plasma transferred arc welding) creates a metallurgical bond between the cladding layer and the substrate. The resulting coatings are free from porosity and can reach hardness levels of 40–60 HRC or higher. It is suitable for nickel-based, cobalt-based, iron-based, and tungsten carbide alloys, meeting a variety of service requirements.

2.Low Dilution, High Efficiency

The dilution rate can be controlled within 5–15% or lower, minimizing the impact of the base material on coating performance. PTA also offers fast deposition rates, making it ideal for automated, large-scale production that reduces manufacturing costs.

3.Process Flexibility

PTA can be applied directly to slightly rusted or oiled surfaces, avoiding extensive pre-treatment. It minimizes defects such as porosity and allows reliable results in demanding industrial environments. The compact equipment design and low maintenance needs make it well-suited for industrial deployment.

4.High Precision Control

By adjusting parameters such as current, gas flow, and powder feed rate, PTA ensures accurate control of coating thickness, quality, and appearance. With concentrated arc energy, the heat-affected zone is small, distortion is reduced, and residual stresses are minimized.

5.Flexible Material Options

PTA supports a wide variety of alloy powders. Its compatibility with hard-to-draw but easy-to-powder materials (such as tungsten carbide) offers additional flexibility in designing custom alloy compositions.

Typical Application Areas

- Construction Machinery: Bucket teeth, blades, and auger shafts requiring wear protection.

- Mining and Cement Industry: Crusher rolls, mixer blades, and conveyor components.

- Energy and Chemical Industry: Valves, pump casings, drill bits, and corrosion-resistant pipes.

- Aerospace and Defense: Tank sprockets, turbine engine parts, and other high-stress components.

- Medical and Tooling: Artificial joints, stamping dies, and precision tooling surfaces.

By significantly extending component service life and reducing replacement costs, PTA cladding supports green remanufacturing practices and reduces resource waste.

FNS Expertise in PTA Technology

At FNS Pipeline Technology Co., Ltd., we are committed to advancing plasma transferred arc welding (PTA) welding solutions and alloy powder products. With a strong R&D foundation and extensive application experience, we deliver reliable solutions for wear resistance, corrosion protection, and high-temperature applications.

Our team works closely with customers to optimize surface engineering processes that increase productivity, lower costs, and ensure long-term performance.

If you would like to learn more about our plasma transferred arc welding (PTA) cladding solutions or discuss a customized project, please contact our professional team today.