Plasma Cladding Solutions for TBM Cutter Tools

The shield tunneling method, commonly known as the TBM (Tunnel Boring Machine) method, is a complete mechanized tunneling system centered on shield machines. First conceived in the United Kingdom in the early 19th century, the technology has evolved for over 200 years and is now widely used in underwater tunnels, urban infrastructure, subway systems, and large-scale transportation projects. As tunneling environments become increasingly complex, plasma cladding for TBM cutter tools has become a critical technology for improving cutter durability, reducing replacement frequency, and ensuring stable shield tunneling performance.

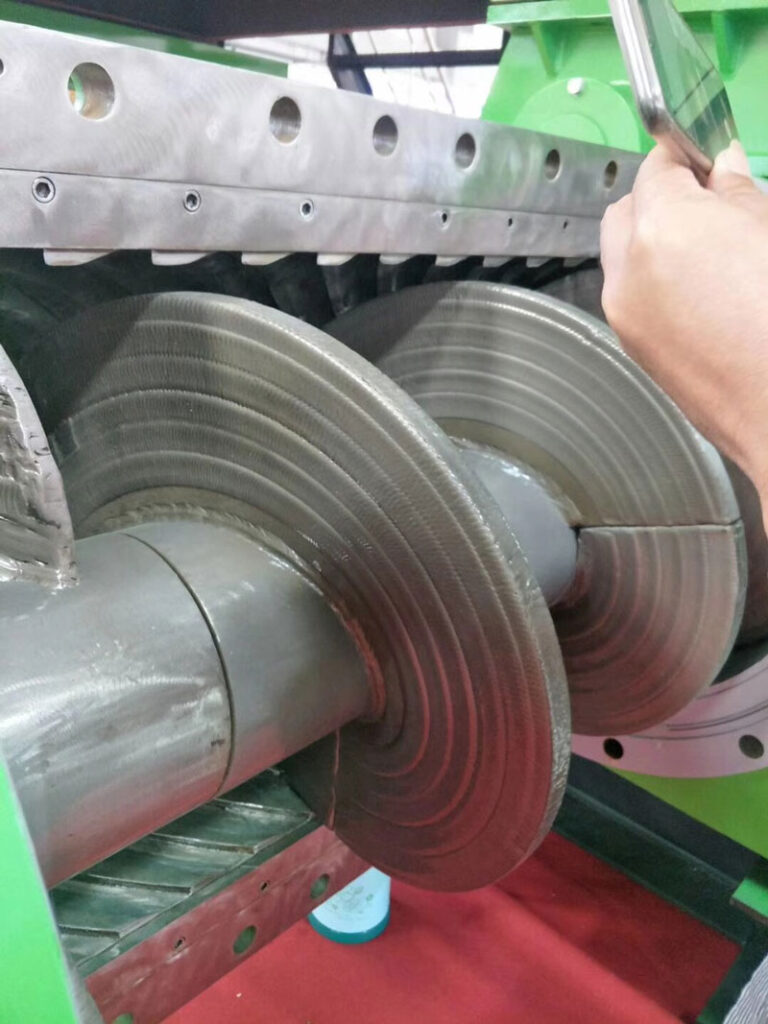

Wear resistant TBM cutter ring after plasma cladding reinforcement

Wear Mechanism Analysis of TBM Cutter Tools

TBM cutters operate under extreme conditions involving high contact stress, impact loading, and abrasive geological media. The primary wear mechanisms of shield machine cutters can be classified into three types:

- Microscopic deformation fatigue wear caused by repeated cyclic loading

- Ploughing abrasive wear, where hard particles cut grooves into the cutter surface

- Pitting abrasive wear, resulting from high-pressure particle impact

Without effective surface reinforcement, cutter tools are exposed to accelerated material loss. This is why plasma cladding for TBM cutter tools is widely adopted to combat abrasive wear, fatigue damage, and impact-related surface failure.

Plasma Cladding Solution for TBM Cutter Rings

To address severe wear challenges, TBM cutter rings are commonly manufactured and refurbished using hardfacing cladding technologies. Among various surface engineering methods, plasma powder cladding has become one of the most effective solutions for cutter reinforcement.

Compared with conventional hardfacing methods, plasma cladding for TBM cutter tools provides precise heat input control, low dilution rates, and dense metallurgical bonding, making it ideal for cutter ring reinforcement under harsh geological conditions.

Cladding materials for TBM cutter rings are typically divided into four alloy systems:

- Cobalt-based alloys

- Nickel-based alloys

- Iron-based alloys

- Copper-based alloys

These alloys are supplied in the form of welding rods, solid or flux-cored wires, fluxes, and alloy powders. Compared with conventional welding processes, plasma arc cladding with alloy powder offers superior control and performance for high-demand tunneling applications.

Plasma-coated reinforced wear-resistant propeller blades

Advantages of Plasma Powder Cladding Technology

By using a high-energy plasma arc as the heat source and alloy powder as the filler material, plasma cladding offers several technical advantages over traditional hardfacing methods:

- High deposition efficiency and fast cladding speed

- Controllable penetration depth with low dilution rate

- Smooth and dense cladding layer, achieving single-pass thickness from 0.5 to 5 mm

- Stable process performance, producing pore-free, defect-free coatings

- Wide material adaptability, supporting cobalt-, nickel-, iron-, and copper-based powders

- Custom alloy formulation, optimized for specific geological and wear conditions

- Excellent automation compatibility, reducing labor intensity

These advantages make plasma cladding an ideal solution for TBM cutter ring wear resistance enhancement.

Plasma Cladding Equipment Solutions by FNS Pipeline Technology

FNS Pipeline Technology Co., Ltd. provides a complete range of automated plasma cladding systems tailored for tunneling and heavy-duty industrial components.

Spiral Blade Plasma Cladding System

Designed for reinforcing spiral blades and auger components, this system is widely used for TBM screw conveyors, feeder screws, and reamer tools, significantly extending component service life.

Robotic Plasma Cladding with Offline Programming

For customers with diverse product types and complex geometries, robotic plasma cladding systems with offline programming dramatically reduce setup time and improve operational efficiency while ensuring consistent coating quality.

Multi-Station Plasma Cladding Machines

Multi-station automated plasma cladding remanufacturing lines enable unmanned, high-efficiency production for large-scale manufacturers. These systems minimize labor requirements while maintaining continuous, stable output.

Reliable Partner for TBM Cutter Wear Protection

With extensive experience in plasma cladding for TBM cutter tools, FNS Pipeline Technology delivers engineered solutions that combine advanced surface metallurgy with intelligent automation. Our systems help tunneling contractors and equipment manufacturers improve cutter durability, reduce maintenance costs, and ensure stable tunnel excavation performance.