Repairing a Titanium Agitator Shaft Using Laser Cladding Technology

At FNS Pipeline Technology Co., Ltd., we are committed to delivering the most advanced surface engineering solutions to meet our customers’ highly specific and challenging requirements. Recently, a petrochemical client required the restoration of a titanium agitator upper shaft operating under extreme production conditions for technical plastics. This complex repair case required a custom-made, high-precision solution—one that traditional methods simply could not achieve reliably.

1. Background: A Demanding Repair Environment

The agitator upper shaft plays a critical role, transmitting torque between the motor and the mixer shaft. The worn area corresponded precisely to the mechanical seal housing—a region where dimensional accuracy is essential for proper sealing and long-term operational safety.

The operating conditions of the reactor were particularly harsh:

- Maximum temperature: 190°C

- Internal pressure: 20 bar

- Base material: Grade 7 titanium

- Required restoration material: Grade 1 titanium, chosen for its excellent weldability and high purity.

Given the thermal sensitivity and reactivity of titanium alloys, restoring the original diameter of a Grade 7 titanium shaft using Grade 1 titanium filler posed a significant technical challenge.

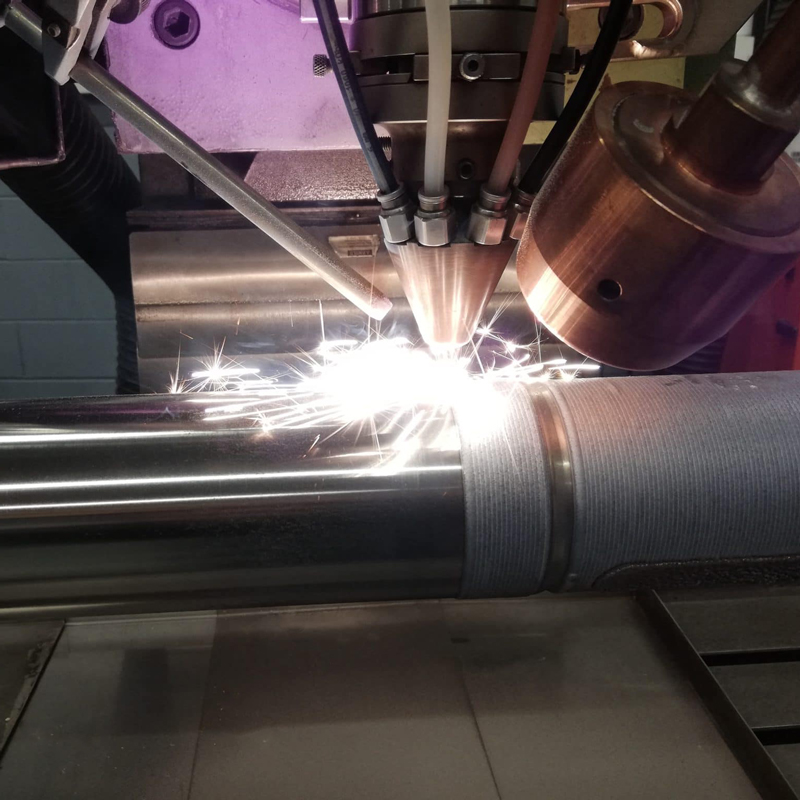

Laser cladding repair on titanium agitator shaft

2. Why Laser Cladding Was the Optimal Solution

The repair demanded a method that could meet three essential criteria:

1) High bonding quality without compromising the titanium substrate

Traditional welding methods risk overheating, distortion, oxidation, or contamination of titanium surfaces.

2) Precise control of heat input

This was essential to avoid altering the metallurgical properties of Grade 7 titanium.

3) A dense, crack-free cladding layer

Necessary to ensure both mechanical integrity and sealing performance.

Laser cladding repair was the only technology that could deliver the required accuracy, stability, and surface quality—without the need for a protective welding chamber.

3. FNS Pipeline Technology’s Engineering Approach

At FNS Pipeline Technology Co., Ltd., our engineering team conducted a detailed assessment of the shaft geometry, titanium grades involved, thermal loads, and sealing requirements. Based on these findings, we developed:

- Custom laser cladding parameters

- A titanium-specific shielding strategy

- Optimized powder feeding conditions

- A controlled thermal profile to avoid microcracking

- A process that eliminates the need for a full enclosed chamber

This tailored approach ensured stable fusion between Grade 1 titanium cladding and the Grade 7 titanium substrate while maintaining dimensional precision and surface integrity.

The result is a durable, high-precision repair solution that restores the shaft’s original diameter and extends its service life under demanding petrochemical operating conditions.

4. Results and Performance

The completed laser-clad layer demonstrated:

- Excellent metallurgical bonding

- Uniform coating thickness and geometry

- No cracks, pores, or oxidation defects

- Improved wear and corrosion resistance

- Reliable sealing compatibility with the mechanical seal housing

The customer validated the repair after reinstallation, confirming that the restored shaft operated smoothly under full reactor load and temperature—demonstrating the long-term effectiveness of FNS’s titanium laser cladding repair solution.

This project highlights FNS Pipeline Technology Co., Ltd.’s capability to solve highly technical repair challenges using advanced laser cladding technology. By restoring a Grade 7 titanium agitator shaft with Grade 1 titanium material—under severe petrochemical conditions—we provided a robust, precise, and economically attractive alternative to component replacement.

FNS will continue to support customers across petrochemical, energy, and high-performance manufacturing industries with innovative surface engineering and repair technologies.