MIG/MAG Pulse Welding – Why It Matters for Modern Fabrication

Before exploring the advantages of MIG/MAG pulse welding, it is useful to understand how a standard arc works. In conventional short-circuit transfer, when the wire electrode touches the base material, a short circuit occurs. The current rises sharply, melting the wire tip and the base material. This process causes the droplet to detach, but also generates spatter and heat that can be difficult to control, especially in low and mid-current ranges.

As current increases, different arc modes appear:

- Short-circuit arc – frequent explosive droplet detachment, higher spatter levels.

- Globular arc – larger droplets, unstable transfer, more rework required.

- Spray arc – fine, stable droplet transfer, almost spatter-free, but limited to high power ranges.

This is where pulse arc welding bridges the gap.

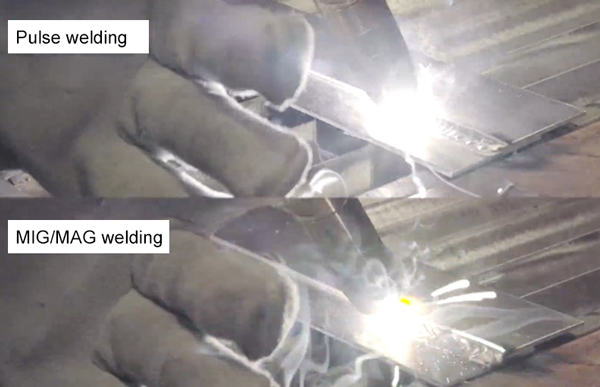

Comparison chart of pulse welding vs standard MIGMAG welding

What Is MIG/MAG Pulse Welding?

Pulse welding is essentially an “electrical trick” designed to replicate the clean transfer of spray arc across the entire power range. Instead of continuous current, the welding machine alternates between a very low base current and brief high-current pulses (typically 1–2 ms).

- The base current keeps the arc stable and the weld pool molten.

- The pulse current generates enough energy for one droplet to detach smoothly into the pool without short-circuiting.

This pulsed oscillation ensures uniform droplet size, minimal spatter, stable arc characteristics, and improved deposition efficiency.

Benefits of MIG/MAG Pulse Welding

| Feature | Standard MIG/MAG Welding | MIG/MAG Pulse Welding |

|---|---|---|

| Spatter generation | High (short circuit & globular) | Very low, almost spatter-free |

| Heat input control | Limited | Adjustable across full power range |

| Weld appearance | Inconsistent | Smooth, clean, professional finish |

| Efficiency on thicker plates | Moderate | Higher travel speed & deposition |

| Aluminum & stainless applications | Difficult to balance parameters | Optimized for low- and high-range welding |

| Multi-pass welding suitability | Moderate | Excellent for layer build-up |

Why Pulse Welding Excels in Aluminum Welding

Aluminum, with its high thermal conductivity, poses challenges for conventional MIG/MAG processes. Standard arcs are often too “cold,” requiring higher wire feed rates that risk excessive reinforcement or burn-through.

With MIG/MAG pulse welding, these issues are minimized:

- Stable penetration without overheating.

- Controlled heat input for thin aluminum sheets.

- Attractive, concave weld appearance.

- Faster welding speed and less rework, making it more cost-efficient.

For industries such as automotive, shipbuilding, and aerospace, this capability is critical in ensuring both structural performance and visual quality.

Practical Advantages in Fabrication

- Reduced spatter → lower rework costs.

- Consistent arc characteristics → from low to high current.

- Better suited for multi-pass welding.

- Improved efficiency → higher travel speeds without sacrificing quality.

The only consideration: since the process avoids short-circuit transfer, some welders note that puddle guidance feels different compared to traditional MIG/MAG. However, with modern machines, the learning curve is short.

FNS Pulse Welding Solutions

At FNS Pipeline Technology, we integrate pulse functionality into our TransSteel multi-process welding systems. This allows fabricators to enjoy the benefits of pulse welding across steel, stainless steel, and aluminum—whether in workshop production or field applications.

The TransSteel Pulse series is designed for welders facing today’s toughest challenges: shortage of skilled professionals, demand for higher quality, and the need to reduce time and costs.

FAQ: MIG/MAG Pulse Welding

Q1: How does pulse welding reduce spatter compared to standard MIG/MAG?

A1: Since the droplet detaches during the pulse without short circuiting, there is almost no explosive spatter, resulting in cleaner welds.

Q2: Is pulse welding suitable for stainless steel and aluminum?

A2: Yes. Pulse technology is especially beneficial for stainless steel and aluminum, providing stable penetration, controlled heat input, and visually smooth weld seams.

Q3: Do welders need special training to use pulse machines?

A3: While pulse welding feels different at first, modern systems adjust parameters automatically. Even operators with limited experience can achieve high-quality welds quickly.

Looking to improve productivity and weld quality while reducing rework?

👉 Contact FNS Pipeline Technology to learn more about our TransSteel Pulse MIG/MAG systems and request a tailored welding solution for your project.