PRODUCT DETAILS

In industries where wear, corrosion, and extreme conditions challenge equipment longevity, overlay cladding materials are critical. The performance of any overlay cladding process depends on selecting the right material for the intended application. At FNS Pipeline, we offer a comprehensive range of overlay cladding materials engineered for specific industrial needs, ensuring reliable surface protection and extended component life.

Our overlay solutions combine material expertise with advanced welding technologies to deliver consistent quality for critical sectors such as oil & gas, petrochemicals, power generation, marine, and heavy industry.

Our Overlay Cladding Materials

Cobalt-Based Overlay Cladding for Wear and Corrosion Resistance

Cobalt-Based Cladding — Trusted for Extreme Wear and Thermal Resistance

Cobalt-based alloys, such as Stellite® 6, are renowned for their excellent wear resistance, high-temperature strength, and ability to withstand thermal shock. These materials are ideal for applications involving sliding wear, galling, and hot corrosion, such as valve components, pump sleeves, and turbine parts.

Key Applications:

- Valve seats and trims

- Pump components

- High-temperature moving parts

Nickel-Based Cladding Applied on Industrial Pump Sleeve

Nickel-Based Cladding — Superior Corrosion and High-Temperature Performance

Nickel-based alloys like Inconel® 625 and Inconel® 718 offer outstanding corrosion resistance and mechanical strength, even at elevated temperatures. They are widely used in chemical processing, offshore oil & gas operations, and sour service pipelines where resistance to aggressive media is critical.

Key Applications:

- Pressure vessels and pipeline components

- Subsea equipment

- Chemical reactors and fittings

Iron-Based Overlay Cladding for Industrial Wear Protection

Iron-Based Cladding — Cost-Effective Wear Protection

Iron-based overlay materials are used for applications where cost-effective protection against moderate wear and corrosion is required. These overlays are often applied to extend the service life of industrial equipment without the higher cost of nickel or cobalt alloys.

Key Applications:

- Wear-resistant liners

- Industrial rollers

- Structural components in general industry

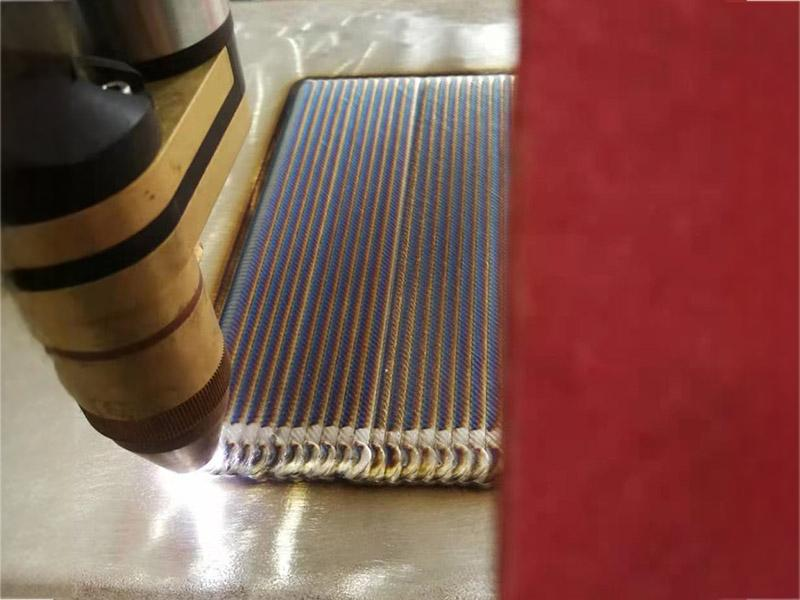

Copper-Based Cladding For Pipeline Prdouct

Copper-Based Cladding — Excellent Thermal Conductivity and Marine Resistance

Copper-based alloys provide excellent corrosion resistance in marine and industrial environments while offering good thermal and electrical conductivity. These materials are commonly used in desalination systems, ship components, and heat exchangers.

Key Applications:

- Heat exchanger tubes

- Marine fittings

- Electrical connectors

Tungsten Carbide Cladding Material

Tungsten Carbide Cladding — Extreme Abrasion and Impact Resistance

Tungsten carbide overlays are applied when maximum wear protection is needed. With extreme hardness and abrasion resistance, tungsten carbide cladding is used in mining, drilling, and heavy industrial applications where conventional materials fail.

Key Applications:

- Mining tools and drill bits

- Wear plates and liners

- Pump impellers and sleeves in abrasive environments

Cladded pipeline with babbitt alloy bearing material cladding for offshore applications

Babbitt Alloy Bearing Material Cladding — Precision and Anti-Friction Performance

Babbitt alloys are specialized bearing materials known for their anti-friction properties. Overlaying with babbitt materials is common in the manufacture and repair of bearings, ensuring smooth operation under load and reducing wear in rotating machinery.

Key Applications:

- Journal bearings

- Heavy-duty machinery components

- Hydroelectric turbine bearings

Why Material Selection Matters in Overlay Cladding

The choice of overlay cladding materials directly affects the performance, durability, and reliability of critical components. At FNS Pipeline, we match each cladding material to the service environment, ensuring optimal bonding, wear resistance, and corrosion protection.

- Our selection process considers:

- Operating temperature

- Corrosive media exposure

- Mechanical wear conditions

- Substrate compatibility

Combined with our strict material storage, inspection, and quality control systems, FNS delivers overlay solutions that meet industry standards and customer expectations.

At FNS Pipeline, we implement strict material management procedures to ensure the quality and reliability of our welding operations.

- Controlled Storage Conditions — All welding materials are stored in a dedicated warehouse with strict temperature and humidity control to preserve material integrity.

- Rigorous Material Inspection — Each batch of welding materials undergoes thorough inspection before being accepted into storage, ensuring compliance with quality standards.

- Order-Based Material Issuance — Welding materials are issued strictly according to task orders, with careful verification before use to maintain traceability and process control.

Our commitment to stringent material handling guarantees consistent welding performance and product quality for every project.

From high-wear surfaces to corrosion-resistant coatings, FNS Pipeline provides overlay cladding materials engineered for real-world industrial challenges. Whether you need cobalt-based overlays for thermal protection or tungsten carbide for abrasion resistance, our material expertise and advanced cladding processes ensure your critical components are protected for the long haul.

Contact us today to discuss your overlay cladding material needs or to learn how FNS Pipeline can help enhance the performance and lifespan of your industrial assets.