20 Years of Cold Metal Transfer (CMT) Welding: Redefining Precision and Efficiency

In 2025, FNS Pipeline Technology Co., Ltd. proudly celebrates the 20th anniversary of Cold Metal Transfer (CMT) welding, a breakthrough technology that has transformed modern welding practices. Since its introduction in 2005, CMT has become synonymous with precision, stability, and versatility, setting new benchmarks for industries requiring high-quality, low-heat-input welding solutions.

What Makes CMT Welding Unique?

Unlike conventional arc welding methods, the CMT process uses a controlled wire retraction movement to achieve precise droplet transfer. This innovation ensures arc stability while significantly reducing heat input. The result is:

- Virtually spatter-free welds – cleaner seams with minimal post-processing

- Lower thermal load on workpieces – reducing distortion and deformation risks

- Capability to weld ultra-thin sheets as thin as 0.3 mm with high accuracy

- Reliable joining of dissimilar materials such as galvanized steel and aluminum

This combination makes CMT a game-changer for manufacturers seeking both productivity and quality.

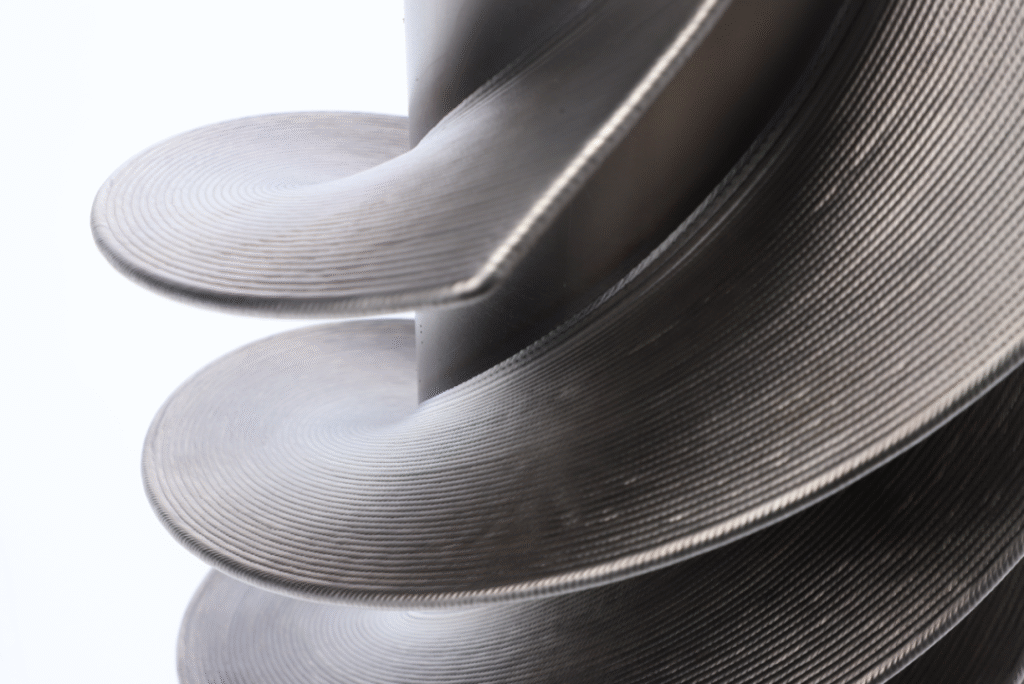

Cold Metal Transfer (CMT) welding process close-up showing

Continuous Innovation: Beyond Standard CMT

Over the last two decades, the R&D team at FNS Pipeline has continuously refined CMT technology, developing advanced process variations tailored for specialized applications:

- CMT Mix & Cycle Step – optimized for enhanced arc control and repeatability

- CMT Cladding – enabling durable overlay solutions for wear and corrosion resistance

- CMT Braze – offering low-heat joining of sensitive materials

- LaserHybrid CMT – combining laser precision with CMT efficiency for high-strength steels and aluminum components

- CMT Additive Pro – engineered for metal 3D printing, pushing additive manufacturing to new frontiers

CMT Welding Compared with Other Welding Techniques

While traditional MIG/TIG and hybrid welding methods are widely used, CMT welding offers unique advantages in precision, stability, and material versatility.

| Feature / Process | Conventional MIG/TIG Welding | LaserHybrid Welding | Cold Metal Transfer (CMT) Welding |

|---|---|---|---|

| Heat Input | High, often causes distortion and spatter | Medium, lower than MIG/TIG | Extremely low, minimal distortion |

| Spatter | Frequent, requires post-weld cleaning | Less than MIG/TIG | Virtually spatter-free |

| Thin Sheet Capability | Limited, risk of burn-through | Better than MIG/TIG | Welds sheets as thin as 0.3 mm |

| Dissimilar Materials | Very limited | Some applications possible | Excellent, e.g., aluminum to galvanized steel |

| Automation Readiness | Medium, requires significant calibration | High, suited for industrial automation | Excellent, seamless integration with robotics |

| Process Speed | Moderate | High | Moderate to High, depending on application |

| Applications | General fabrication, heavy steel structures | Automotive body, aerospace, high-strength steel | Automotive, aerospace, 3D printing, electronics |

Industry Applications of CMT Welding

Today, cold metal transfer welding is a proven solution across multiple industries:

- Automotive: Secure and lightweight joining of thin sheets and aluminum for structural reliability

- Aerospace: Welding of high-strength, lightweight alloys to meet stringent safety and performance standards

- Marine & Energy: Applications where corrosion resistance and durability are critical

- Electronics & 3D Printing: Precision welding for small, complex, and heat-sensitive components

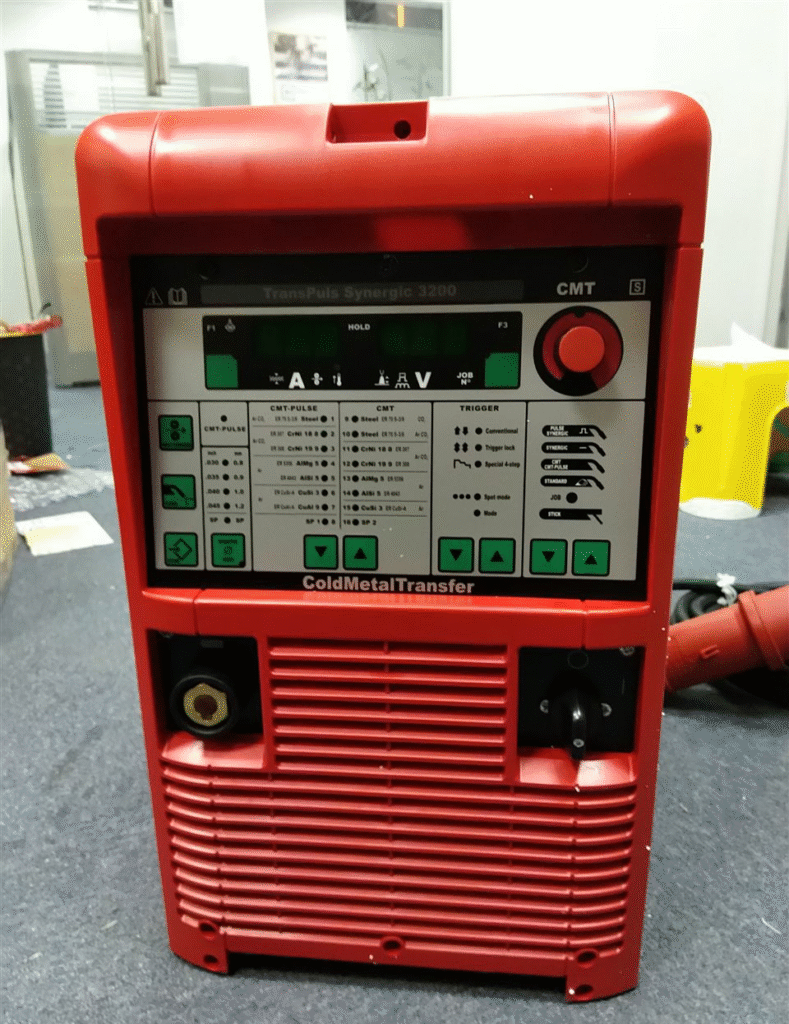

CMT welding machine

Intelligent Welding with WireSense

FNS Pipeline integrates WireSense, an intelligent robotic welding assistant, with CMT technology. In this system, the welding wire acts as a high-precision sensor, detecting deviations in weld positioning and adjusting parameters in real time.

Benefits include:

- Enhanced weld quality and fewer defects

- Reduced rework and scrap rates

- Cost savings in material and production time

- Improved efficiency for robotic welding systems

Why Choose FNS Pipeline for cold metal transfer welding solutions?

With two decades of expertise, FNS Pipeline offers more than just welding processes. We deliver:

- Proven Technology: Backed by continuous innovation and field-tested reliability

- Custom Engineering: Tailored welding solutions for your specific industry needs

- Global Standards: Compliance with ISO, ASME, and API for quality assurance

- Customer Focus: Technical consultation, pilot projects, and long-term service support

Frequently Asked Questions (FAQ)

Q1: What is Cold Metal Transfer (CMT) welding?

A: CMT is an advanced welding process that uses controlled wire retraction to achieve precise droplet transfer, producing low-heat, spatter-free welds.

Q2: Why is CMT ideal for thin and sensitive materials?

A: The reduced heat input minimizes distortion, making it suitable for sheets as thin as 0.3 mm or materials like aluminum.

Q3: Which industries benefit most from CMT?

A: Automotive, aerospace, marine, energy, electronics, and additive manufacturing all leverage CMT for precision and durability.

Q4: Can CMT welding be automated?

A: Yes, especially when combined with robotic systems and WireSense technology, ensuring consistent, high-quality welds.

Looking to upgrade your welding process with the precision and reliability of CMT technology?

👉 Contact FNS Pipeline today for expert consultation and customized welding solutions tailored to your industry.