High-Efficiency Hot-Wire TIG Cladding (Rotating Torch Type) for Industrial Weld Overlay Applications

In industries such as petrochemicals, marine engineering, nuclear power, and aerospace, pipelines and valves are exposed to extreme wear and corrosion. Traditional TIG welding, while reliable, often suffers from low deposition rates, high dilution, and distortion risks-making it less efficient for today’s demanding projects. This is where Hot-Wire TIG Cladding with rotating torch technology comes in. By preheating the filler wire before it enters the weld pool, this advanced weld overlay process significantly improves deposition efficiency, reduces dilution, and ensures superior metallurgical bonding.

FNS Pipeline hot-wire TIG cladding rotating torch system

How the Hot-Wire TIG Cladding Process Works

Our rotating torch cladding systems operate with six Siemens servo axes, ensuring precision movement while the workpiece remains stationary. This method allows for the processing of both regular and irregular-shaped components with no weight limitations.

Key Technical Advantages

- ✅ 2–3× higher deposition efficiency compared with traditional TIG

- ✅ Reduced dilution and heat input, minimizing base metal distortion

- ✅ Handles irregular and large workpieces (up to Ø3000 mm)

- ✅ Applicable to a wide range of alloys (stainless, duplex, nickel, cobalt, bronze)

- ✅ Uniform and reliable overlay thickness for critical applications

Comparison: Traditional TIG vs. Hot-Wire TIG Cladding

| Feature | Traditional TIG | Hot-Wire TIG (Rotating Torch) |

|---|---|---|

| Deposition Efficiency | Low | High (2–3× improvement) |

| Base Metal Dilution | Higher | Lower |

| Heat Input | High | Reduced |

| Distortion Risk | More likely | Significantly reduced |

| Workpiece Weight Limit | Limited | No limitations |

| Component Shapes | Mostly regular | Handles irregular & complex parts |

Applications & Industries

It is widely applied to extend service life and reduce maintenance costs in:

- Oil & Gas: Blowout preventer (BOP) valves, subsea tree components, pipeline fittings

- Petrochemical Plants: Heat exchangers, tube sheets, pressure vessels

- Power Generation: Turbine casings, nuclear reactor components

- Marine Engineering: Pump housings, ship valves, seawater piping

- Mining & Heavy Industry: Slurry pumps, elbows, tees, wear-resistant parts

Supported Cladding Materials

Our advanced systems can process a wide range of corrosion- and wear-resistant alloys, including:

- Stainless Steel: ER307, ER308, ER309, ER310, ER316, ER321, ER347, ER385, ER410, ER431, ER440, ER630

- Duplex Stainless Steel: 2209, 2594

- Nickel-Based Alloys: Ni1, Inconel 600/625/52M, Incoloy 800/825, Monel NiCu7, Hastelloy B-2/C22/C276, Ultimet wire

- Cobalt-Based Alloys (Stellite Alloys): Stellite 21 (CoCr-E), Stellite 25, Stellite 12 (CoCr-B), Stellite 6 (CoCr-A), Stellite 1 (CoCr-C)

- Copper-Based Alloys: Aluminum Bronze (S214), Tin Bronze (S213), Silicon Bronze (S211), Cupronickel (CuNi), Nickel-Aluminum Bronze

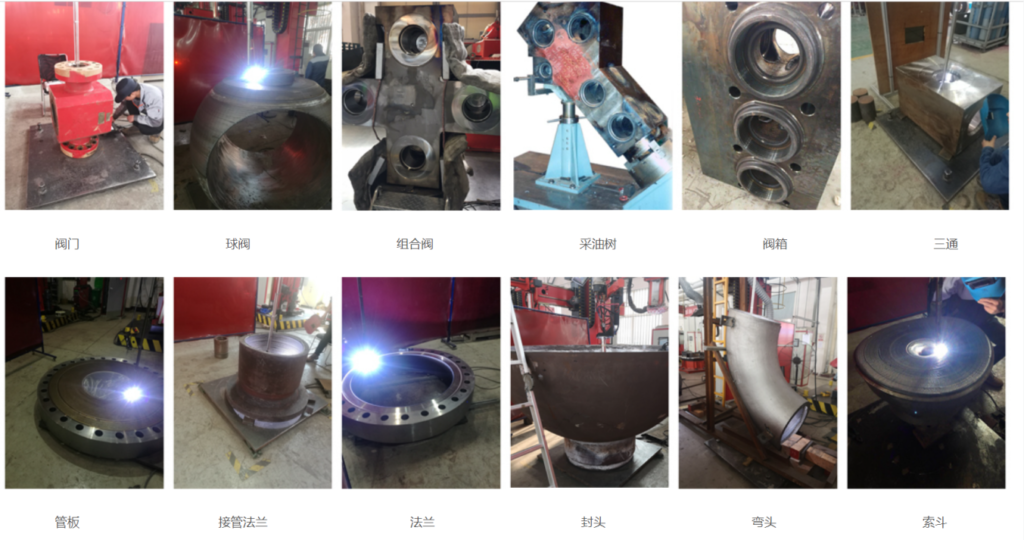

Hot-Wire TIG Cladding For Pipeline Products

Why Choose FNS Pipeline?

At FNS Pipeline, we specialize in weld overlay technology for pipes, valves, and pressure vessels. Our hot-wire TIG cladding systems combine precision automation with deep metallurgical expertise to deliver:

- ✅ Flawless metallurgical bonding

- ✅ Tight tolerance machining after cladding

- ✅ Full quality traceability & NDT inspection

- ✅ Customized solutions for complex operating environments

FAQ (Frequently Asked Questions)

- Q1: What is the main advantage of hot-wire TIG cladding over traditional TIG?

Hot-wire TIG preheats the wire, allowing faster deposition, lower dilution, and less distortion—ideal for large and complex components. - Q2: Which alloys are suitable for hot-wire TIG cladding?

We support a wide range, including stainless steels, duplex steels, Inconel, Hastelloy, Monel, Stellite, and copper-based alloys. - Q3: What industries benefit the most from this technology?

Oil & gas, petrochemical, nuclear power, aerospace, and marine engineering industries where long service life and corrosion resistance are critical. - Q4: What is the maximum workpiece size?

Outer diameter up to Φ3000 mm with no weight limitations.

Looking for a reliable partner in weld overlay technology?

👉 Contact NS Pipeline Technology Co., Ltd. today to discuss your project requirements. Our experts will recommend the optimal hot-wire TIG cladding solution tailored to your specific operating conditions.