Additive Welding Process

- Hot-Wire TIG Cladding Process (Rotary Table Type)

The hot-wire TIG cladding process is an efficient overlay welding technique based on traditional tungsten inert gas (TIG) welding. It involves preheating the welding wire before feeding it into the molten pool, significantly enhancing deposition efficiency, reducing base metal dilution, and lowering heat input to minimize welding distortion. This process has been successfully applied in petrochemical, marine engineering, power construction, nuclear power, and aerospace industries.

Additive Welding Process

Process Details

Our company operates multiple hot-wire TIG cladding systems (rotary table type), featuring high-performance Siemens motors, a high-precision servo rotary table, a servo cross-manipulator, an Austrian Fronius hot-wire TIG power source, and an HMI touchscreen controller. This setup ensures high control precision, excellent process repeatability, and low dilution, delivering maximum economic benefits for customers.

Cladding Process

Automatic hot-wire TIG cladding

Applicable Workpieces

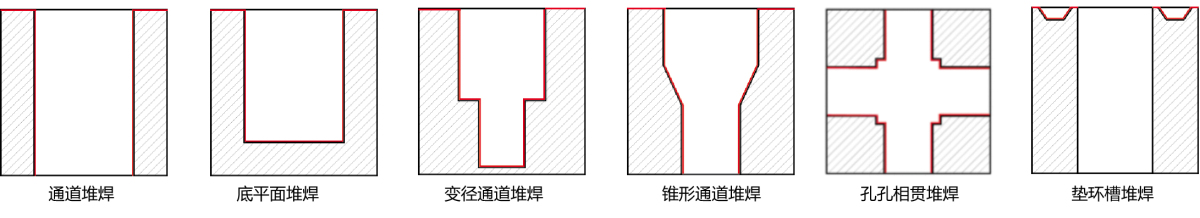

Valves, valve covers, elbows, tees, pipe inner walls, flanges (for both internal bore and outer diameter cladding)

cladding product

Applicable Product Specifications

Inner bore/deep hole cladding: ≥ Φ25 mm

Maximum workpiece height: 1200 mm

Maximum workpiece outer diameter: ≤ Φ1400 mm

Maximum workpiece weight: 5000 kg

Applicable Cladding Materials

Stainless Steel: ER307, ER308, ER309, ER310, ER316, ER321, ER347, ER385, ER410, ER431, ER440, ER630

Duplex Stainless Steel: 2209, 2594

Nickel-Based Alloys: Ni1, Inconel 600/625/52M, Incoloy 800/825, Monel NiCu7, Hastelloy B-2/C22/C276, Ultimet wire

Cobalt-Based Alloys (Stellite Alloys): Stellite 21 (CoCr-E), Stellite 25, Stellite 12 (CoCr-B), Stellite 6 (CoCr-A), Stellite 1 (CoCr-C)

Copper-Based Alloys: Aluminum Bronze (S214), Tin Bronze (S213), Silicon Bronze (S211), Cupronickel (CuNi), Nickel-Aluminum Bronze