Choosing the Right Clad Pipe Supplier: Expertise, Quality, and Long-Term Reliability

In critical industries such as oil & gas, petrochemical, power generation, and mining, clad pipes and fittings are not just components — they are the lifeline of entire systems. A single failure caused by poor-quality cladding can result in unplanned shutdowns, safety risks, and millions of dollars in downtime. This is why choosing the right clad pipe supplier is more than a purchasing decision; it is an investment in long-term reliability, safety, and operational efficiency.

weld overlay cladding process for clad pipes

The Foundation of Trust: Backed by the Fronius Group

The strength of a supplier lies in its foundation. FNS Pipeline inherits the global engineering excellence of the Fronius Group, a company with over 75 years of innovation in welding technology, solar energy, and battery systems.

With a reputation built on Made in Austria quality and technical mastery, Fronius provides FNS Pipeline with direct access to world-class weld overlay technology, advanced cladding processes, and strict quality management systems.

This foundation ensures every pipe and fitting we deliver is engineered for maximum durability, even under the harshest operating conditions.

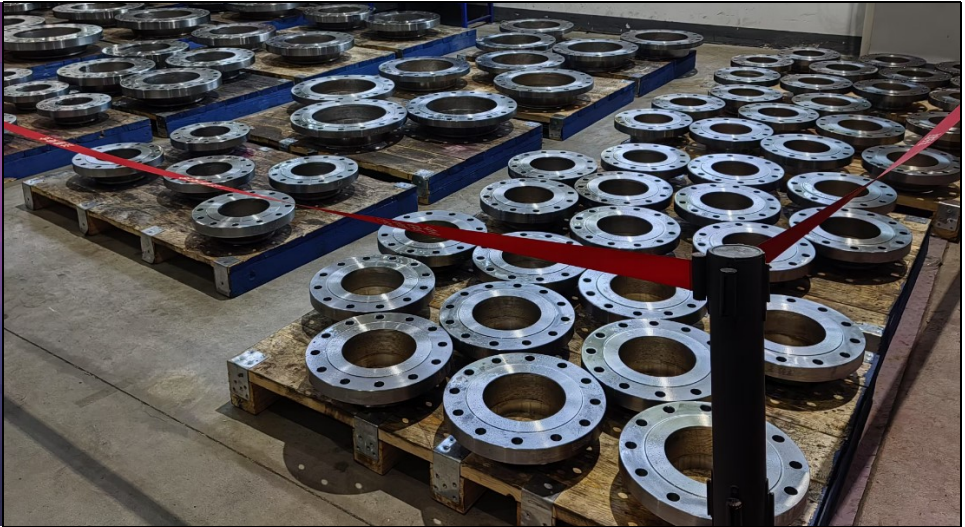

The clad flange products produced by FNS

FNS Pipeline: Specialized in Weld Overlay Cladding

Unlike general manufacturers, FNS Pipeline focuses exclusively on weld overlay technology for clad pipes and fittings. This specialization allows us to go deeper into material science, welding metallurgy, and real-world performance challenges.

- For sour gas service in upstream oil fields, we apply Inconel 625 or Hastelloy cladding to resist sulfide stress cracking.

- For abrasive mining slurries, we engineer chromium carbide overlays for superior wear protection.

- For offshore seawater systems, we deliver Duplex or Titanium clad fittings that ensure long-term corrosion resistance.

Our mission is not just to supply clad pipes — but to deliver purpose-built solutions that extend equipment life, reduce maintenance costs, and enhance operational safety.

Key Factors When Choosing a Clad Pipe Supplier

| Factor | Risk with an Unreliable Supplier | FNS Pipeline Advantage |

|---|---|---|

| Cladding Bond Quality | Weak bonding, risk of delamination | Verified metallurgical bonding via advanced weld overlay technology |

| Material Selection | Limited alloy options, poor suitability | Wide range: Inconel, Hastelloy, Chromium Carbide, Duplex Stainless, Titanium |

| Traceability | Incomplete certification and records | Full EN 10204 3.1 / 3.2 certification, NDT documentation |

| Quality Control | Minimal inspection | 100% dimensional, hardness, and NDT checks |

| Delivery Reliability | Frequent delays | Annual capacity >500 tons, proven on-time delivery record |

Case Example: Offshore Clad Pipe Supply

Recently, FNS Pipeline delivered over 200 tons of Inconel 625 clad pipes and fittings for an offshore sour service project in the Middle East. The products were manufactured with uniform overlay thickness tolerance (±0.5 mm) and underwent 100% ultrasonic and radiographic inspection. The result: reliable long-term operation with zero failures reported during commissioning.

This is the kind of assurance that only a specialized supplier can provide.

High-performance weld overlay elbow fittings manufactured by FNS

Why FNS Pipeline is Your Trusted Partner

✔ Backed by 75+ years of welding expertise from the Fronius Group

✔ Specialized in weld overlay cladding for pipes and fittings

✔ Full compliance with international standards (ASME, ASTM, API)

✔ Proven track record with global oil & gas, petrochemical, and mining clients

✔ Custom-engineered solutions to match project-specific conditions

Frequently Asked Questions (FAQ)

- Q1: What standards do your clad pipes comply with?

Our clad pipes and fittings meet ASME, ASTM, API, and EN standards, with full EN 10204 3.1/3.2 certification. - Q2: How do you ensure cladding quality?

We apply advanced weld overlay technology, followed by 100% NDT inspection (ultrasonic, radiographic, and hardness tests) to ensure flawless metallurgical bonding. - Q3: Can you provide customized solutions?

Yes. We offer tailored solutions in terms of pipe dimensions, cladding thickness, and alloy selection, ensuring the product fits your exact project needs. - Q4: What industries use your clad pipes and fittings?

We serve oil & gas, petrochemical, offshore platforms, power generation, mining, and desalination plants worldwide.

If your project requires clad pipes and fittings that perform under extreme conditions, partner with a clad pipe supplier who combines global engineering excellence with specialized weld overlay expertise.

📩 Contact FNS Pipeline today to request a quote or technical datasheet and secure reliable clad piping solutions for your next project.