What is Cladding for Pipes?

Cladding for pipes is a specialized metallurgical process that bonds a corrosion-resistant or wear-resistant alloy layer to the inner or outer surface of a carbon steel or low-alloy steel pipe. This is typically achieved through weld overlay technology, where alloys such as stainless steel, duplex stainless steel, or nickel-based materials are deposited onto the base metal. The result is a composite structure: the pipe retains the mechanical strength and cost-effectiveness of the carbon steel substrate while gaining the durability and performance of a high-quality alloy layer.

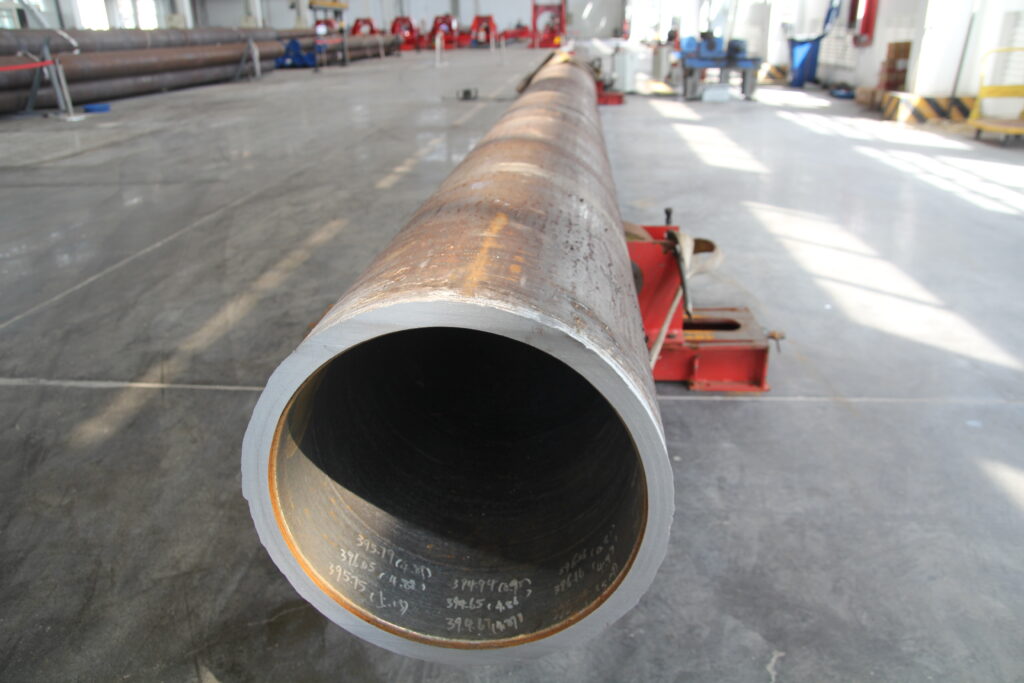

Pipe Cladding Samples

It is important to distinguish cladding from other surface protection methods such as linings or coatings. While coatings (e.g., paint, epoxy, or polymer) and linings (e.g., rubber or glass-reinforced materials) provide a physical barrier, they are generally less durable under extreme pressure, temperature, or corrosive environments. In contrast, a weld overlay pipe forms a metallurgically bonded alloy layer that becomes an integral part of the pipe, offering superior adhesion, crack resistance, and long-term reliability.

When combined with corrosion-resistant alloys, the product is often referred to as a CRA clad pipe. These pipes are widely used in industries requiring high resistance to corrosive media, such as offshore oil and gas pipelines, refineries, and chemical plants, where traditional carbon steel pipes would rapidly deteriorate.

Pipe Cladding Materials

Choosing the right material is critical to the performance and longevity of cladding for pipes. Different industrial environments require specific alloys to resist corrosion, wear, and high temperatures. Commonly used pipe cladding materials include:

Stainless Steel

304L and 316L: Widely used for moderate corrosion resistance and cost-effective solutions. 316L is especially suitable for acidic and chloride-containing environments.

904L: Offers higher resistance to strong acids such as sulfuric acid, making it ideal for chemical processing pipelines.

Duplex 2205: Combines high strength with excellent corrosion resistance, particularly against stress corrosion cracking and chloride-induced pitting.

Nickel Alloys

Inconel 625: Exceptional resistance to oxidation and corrosion in high-temperature and highly corrosive environments, commonly used in offshore oil and gas pipelines.

Incoloy 825: Excellent resistance to acids, chlorides, and sulfides, suitable for chemical and petrochemical applications.

Hastelloy C-22/C-276: Highly resistant to aggressive chemicals and oxidizing media, ideal for the most challenging chemical processes.

Cobalt Alloys

Stellite 6: Known for extreme wear resistance and high-temperature durability, often used in slurry pipelines or components exposed to severe erosion and abrasion.

Selection Criteria

Selecting the appropriate cladding material depends on operating conditions:

Corrosive Media – Types of chemicals, presence of chlorides, H₂S, CO₂, or seawater.

Temperature – High-temperature environments require alloys with strong oxidation and creep resistance.

Pressure and Flow – High-pressure or abrasive flow conditions demand wear-resistant and mechanically robust cladding.

Careful evaluation of these factors ensures that a CRA clad pipe is customized to deliver optimal performance, long service life, and cost efficiency in demanding industrial applications.

Cladding Processes for Pipes

The performance of cladding for pipes largely depends on the chosen cladding process. Selecting the right method ensures that the overlay layer adheres properly, maintains its chemical composition, and achieves the desired corrosion or wear resistance.

Cladding Process for Pipes

GTAW (Gas Tungsten Arc Welding / TIG) – Provides precise control, low heat input, and minimal dilution, ideal for critical applications or small-diameter pipes.

GMAW (Gas Metal Arc Welding / MIG) – High deposition rates, suitable for inner and outer pipe surfaces, often automated for consistent quality.

SAW (Submerged Arc Welding) – Efficient process for large-diameter pipes or external cladding, producing thick and uniform layers.

PTAW (Plasma Transferred Arc Welding) – High-precision process commonly used for hard-facing or wear-resistant alloys.

Laser Cladding—Laser cladding is an advanced process that delivers highly precise and low-dilution cladding layers. A focused laser beam melts alloy powder or wire onto the pipe surface, forming a metallurgically bonded coating with minimal heat-affected zone.

Common Challenges & Solutions in Pipe Cladding

While cladding for pipes provides excellent corrosion and wear resistance, the process involves technical challenges that must be carefully managed. Key challenges include:

Dilution Control

Maintaining the chemical composition of the overlay layer is critical. Excessive dilution of the base metal can compromise performance. Solutions include:

Selecting proper welding parameters, such as heat input and travel speed

Using multi-pass welding techniques with controlled layer thickness

Choosing precise alloys and filler materials for the intended service environment

Crack Prevention

Cracking may occur due to thermal stress, hydrogen embrittlement, or rapid cooling. Preventive measures include:

Preheating the base pipe to reduce thermal gradients

Applying post-weld heat treatment (PWHT) to relieve residual stresses

Monitoring welding parameters, including interpass temperature and cooling rate

Inspection & Testing

Comprehensive testing verifies the quality and performance of the cladding layer:

UT (Ultrasonic Testing) – Detects internal defects such as porosity, lack of fusion, or cracks

RT (Radiographic Testing) – Evaluates weld integrity and hidden flaws

PMI (Positive Material Identification) – Confirms alloy composition of the clad layer

Hardness Testing – Ensures mechanical properties meet design requirements

By carefully addressing these challenges, FNS Pipeline delivers high-quality CRA clad pipes that meet the strictest industrial standards, providing reliable corrosion and wear protection for pipelines in oil & gas, petrochemical, and power generation industries.

How FNS Pipeline Delivers Reliable Cladding Solutions

At FNS Pipeline, we leverage over 20 years of expertise in pipeline overlay cladding to provide industry-leading solutions for demanding pipeline applications. Our extensive experience ensures every project—from design to delivery—meets the highest standards of quality and reliability.

We offer a wide range of materials, including stainless steel, nickel alloys, and duplex stainless steel, enabling us to provide tailored solutions for various operating environments. Whether you need corrosion resistance for offshore oil and gas pipelines, high-temperature durability for power plants, or chemical resistance for petrochemical facilities, we have the right material and process to meet your requirements.

Quality is at the core of our operations. All weld overlay pipes and CRA clad pipes undergo strict inspection and testing, including 100% non-destructive testing (NDT) and full material traceability. This ensures every clad pipe we deliver consistently meets project specifications and industry standards.

Additionally, we provide customized services for oil & gas, petrochemical, and power industries, including flexible cladding solutions, project consulting, and technical support. By combining advanced cladding technology, precise material selection, and rigorous quality control, FNS Pipeline ensures long-lasting, high-performance pipelines that maximize safety, efficiency, and cost-effectiveness.

Contact FNS Pipeline today to discuss your project and get a customized cladding solution that meets your operational needs.