Common Cladding Techniques for Pressure Vessels

Common cladding techniques for pressure vessels are essential to ensure durability, safety, and long-term cost efficiency. In industries such as petrochemical, power generation, and marine engineering, cladding protects vessel surfaces against corrosion, erosion, and high-temperature damage. Selecting the right overlay method directly impacts performance, maintenance cycles, and regulatory compliance.

Key Cladding Methods for Pressure Vessels

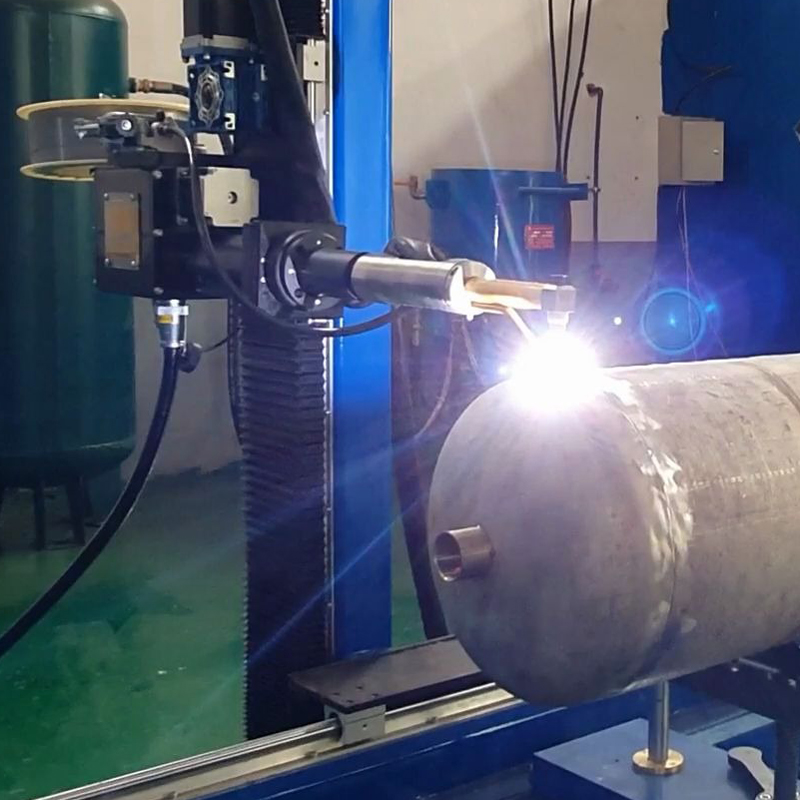

1. Gas Metal Arc Welding (GMAW) Overlay

This method uses a consumable wire electrode and shielding gas to protect the molten pool.

Advantages:

- High productivity and cost efficiency

- Consistent weld quality

- Easily automated for large-scale production

Application: Widely used in petrochemical and general pressure vessel fabrication where efficiency and quality balance is critical.

Gas Metal Arc Welding (GMAW) Overlay for Pressure Vessel

2. Arc Manual Welding (AMAW) Overlay

In this process, electrodes are manually controlled to perform multi-position cladding (flat, vertical, horizontal, overhead).

Key Points:

- Typically involves multi-layer deposition: the first layer is affected by base metal dilution, while subsequent layers better reflect the electrode’s properties.

- Suitable for localized repair welding and smaller-scale projects.

Application: Pressure vessels requiring manual repair or customized cladding in difficult welding positions.

3. Automatic TIG (Auto TIG) with Solid Wire

A fully automated filler-wire tungsten inert gas welding process, where the workpiece rotates while the torch oscillates.

Advantages:

- Precise cladding of small-diameter (50–150 mm) vessel nozzles and inner walls

- Produces high-quality overlays with fine control

Limitations: Low deposition rate and shallow penetration, leading to lower productivity.

Application: Ideal for small-diameter pipes and vessel internals requiring precision cladding.

4. Submerged Arc Welding (SAW) Strip Cladding

This method uses a metal strip electrode (30–60 mm wide, 0.4–0.6 mm thick) under a flux layer.

Advantages:

- Produces flat, defect-free overlay surfaces

- Very low dilution rate, ensuring high-purity cladding layers

- Higher deposition efficiency compared to Auto TIG

Application: Large-diameter pressure vessel shells and heads requiring high-quality, corrosion-resistant overlays.

5. Electroslag Welding (ESW) Strip Cladding

Unlike SAW, ESW relies on the resistance heat of molten flux instead of an arc.

Advantages:

- Minimal carbon pickup due to low-carbon flux and shallow penetration

- Superior corrosion resistance compared to SAW

- High deposition efficiency for thick overlays

Application: Large pressure vessels in corrosive service conditions, such as desulfurization towers, reactors, and storage tanks.

Comparison of Cladding Techniques for Pressure Vessels

| Cladding Method | Deposition Rate | Dilution | Typical Applications | Key Advantages |

|---|---|---|---|---|

| GMAW | High | Moderate | General vessel fabrication | Efficient, cost-effective, automation-friendly |

| AMAW | Moderate | Higher (first layer) | Repair, small jobs | Flexible, multi-position capability |

| Auto TIG | Low | Very Low | Nozzles, small pipes | High precision, clean welds |

| SAW (Strip) | High | Very Low | Vessel shells, heads | Flat overlays, low dilution |

| ESW (Strip) | Very High | Very Low | Large vessels in corrosive environments | Minimal carbon pickup, superior corrosion resistance |

Why Choosing the Right Cladding Process Matters

- Customer Pain Point: Pressure vessels face corrosion, erosion, and high-pressure environments that can lead to early failures and costly downtime.

- Solution: Selecting the correct cladding process ensures extended lifespan, lower maintenance costs, and compliance with safety regulations.

- Value for Clients: By applying the right cladding technology, operators can avoid unplanned shutdowns, reduce replacement costs, and meet the stringent requirements of petrochemical and energy sectors.

Frequently Asked Questions (FAQ)

Q1: Which cladding method is best for large pressure vessels?

For large vessels, SAW strip cladding and ESW strip cladding are preferred due to high efficiency, low dilution, and superior corrosion resistance.

Q2: Can manual welding (AMAW) still be used in modern pressure vessel production?

Yes, AMAW is valuable for localized repairs and hard-to-reach areas, though it is less efficient than automated methods.

Q3: Why is low dilution important in pressure vessel cladding?

Low dilution ensures the cladding alloy retains its corrosion resistance and mechanical properties without being compromised by mixing with the base metal.

Q4: What industries benefit most from advanced cladding technologies?

Petrochemical, power generation, nuclear, and marine industries rely heavily on cladded pressure vessels for long-term reliability.

At FNS Pipeline, we specialize in advanced weld overlay cladding technologies tailored for pressure vessel applications. Our expertise in SAW, ESW, TIG, and GMAW overlays ensures that your equipment achieves maximum service life and superior corrosion protection.

👉 Contact us today for a technical consultation or request a customized solution for your pressure vessel project.