Differences and Selection Between Oxy-Acetylene spray welding and Plasma Cladding

In modern surface engineering technology, both Oxy-Acetylene spray welding and plasma cladding play vital roles across industries such as machinery manufacturing, petrochemicals, and aerospace. At FNS Pipeline Technology Co., Ltd., we specialize in the research and industrial application of these technologies, offering customers tailored solutions that enhance durability, performance, and cost efficiency.

This article compares the two processes across five key dimensions: heat source, bonding strength, dilution rate, powder utilization, and material adaptability.

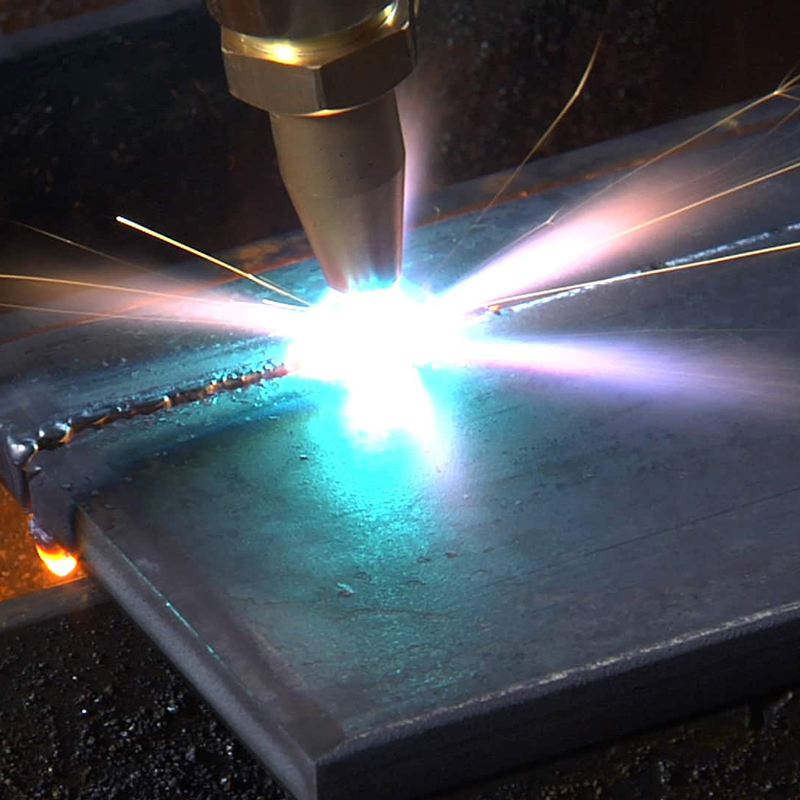

Oxy-acetylene welding process flame

1. Heat Source Characteristics

- Oxy-Acetylene spray welding relies on the combustion of oxygen and acetylene, producing a flame core of about 3,100°C. However, the effective heat for the workpiece is usually below 1,300°C, resulting in a relatively mild thermal effect. This minimizes distortion and reduces the size of the heat-affected zone.

- Plasma cladding, on the other hand, uses a compressed arc plasma that can reach temperatures of 20,000°C with extremely high energy density. This enables rapid melting and ensures high-quality metallurgical bonding.

At FNS, we carefully select the appropriate heat source based on workpiece materials and operational requirements to guarantee compatibility and quality.

2. Bonding Strength

Bonding strength is crucial in evaluating surface cladding quality.

- Oxy-Acetylene spray welding typically forms a semi-metallurgical bond with strength around 300 MPa, suitable for standard operating conditions.

- Plasma cladding achieves a fully metallurgical bond with much higher bonding strength, making it ideal for components under high stress, heavy wear, and severe service conditions.

Through metallographic analysis and mechanical testing, FNS confirms that plasma cladding produces a dense microstructure at the bonding interface, ensuring superior performance.

FNS cladding solutions for surface engineering

3. Dilution Rate & Powder Utilization

- Dilution Rate:

- Oxy-Acetylene spray welding: nearly zero dilution, maintaining the original coating properties.

- Plasma cladding: 5–15% dilution due to high temperatures, requiring strict process control.

- Powder Utilization:

- Oxy-acetylene: 60–70%

- Plasma cladding: up to 90% with precise powder feeding.

At FNS, we optimize gun design and process parameters to further improve material utilization, effectively lowering production costs.

4. Material Adaptability

- Oxy-Acetylene spray welding requires self-fluxing alloy powders.

- Plasma cladding supports a wider range of materials including stainless steel, nickel-based alloys, and metal-ceramic composites, extending its application scope.

By leveraging this flexibility, FNS develops customized coating solutions that meet the unique needs of different industries.

5. Technology Comparison at a Glance

| Aspect | Oxy-Acetylene spray welding | Plasma Cladding |

|---|---|---|

| Heat Source | Oxy-acetylene flame (~3,100°C, effective <1,300°C) | Plasma arc (~20,000°C, very high energy density) |

| Bonding Strength | Semi-metallurgical (~300 MPa) | Full metallurgical (much higher) |

| Dilution Rate | ~0% | 5–15% |

| Powder Utilization | 60–70% | Up to 90% |

| Material Flexibility | Self-fluxing alloys only | Wide range: stainless steel, Ni-based, ceramics |

Practical Recommendations

- For general repair and protective coatings: Oxy-acetylene welding offers a cost-effective and simple solution.

- For critical, high-performance parts: Plasma cladding ensures superior strength, wear resistance, and extended service life.

At FNS Pipeline Technology, our portfolio covers nickel-based, iron-based, and copper-based alloys, delivering excellent resistance to wear, corrosion, and high temperatures.

FAQ

Q1: Which process is more economical for large-scale coating applications?

A1: Oxy-Acetylene spray welding is generally more cost-efficient, especially for low-demand repairs and protective layers.

Q2: Does plasma cladding always outperform oxy-acetylene welding?

A2: Not necessarily. Plasma cladding provides superior bonding and performance but at higher cost. The choice depends on your workpiece material, service environment, and budget.

Q3: Can FNS provide customized coating solutions?

A3: Yes. Our engineering team develops tailor-made surface treatments to meet customer-specific requirements in mechanical, petrochemical, and aerospace industries.

Looking for a reliable partner in surface engineering and cladding technology?

👉 Contact FNS Pipeline Technology Co., Ltd. today for consultation and customized solutions that help you reduce costs, extend service life, and improve efficiency.