FNS iWave Welding Platform – TIG DynamicWire, Multiprocess PRO & CMT Additive Innovations

FNS Pipeline Technology Co., Ltd. proudly introduces the iWave Welding Platform, an intelligent all-in-one system designed for automated applications. Following the successful launch of the manual version two years ago, the robotic-ready iWave Welding Platform marks a major step forward. It not only inherits the proven reliability of the original system but also introduces game-changing innovations for TIG, multiprocess welding, and additive manufacturing. This breakthrough reflects FNS’s commitment to advancing welding automation across industries.

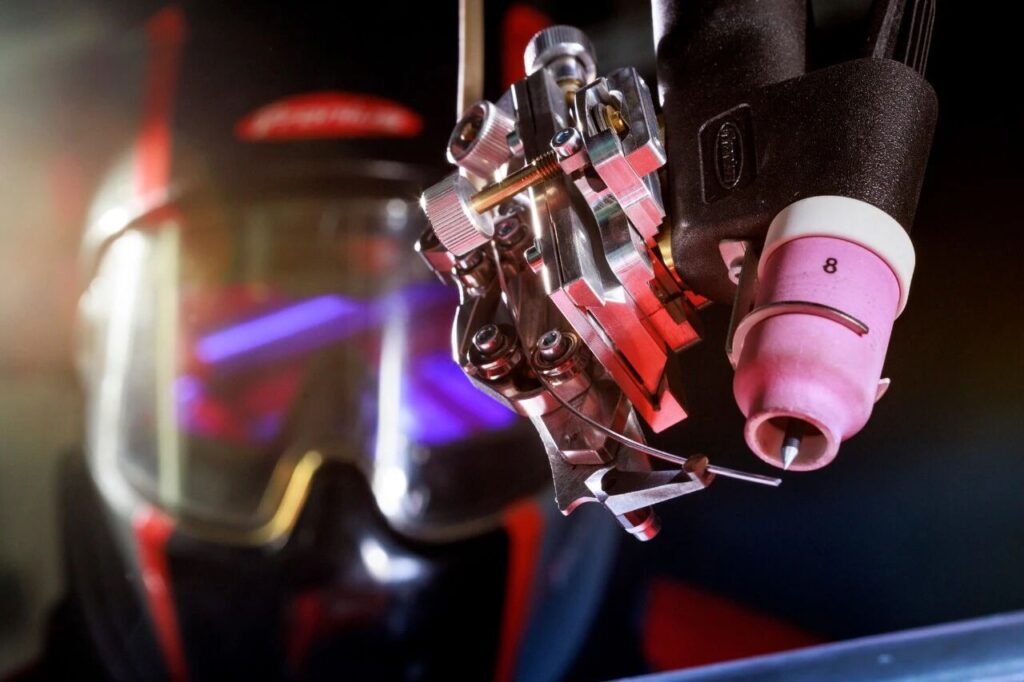

FNS iWave welding platform with robotic TIG DynamicWire system

Highlight 1: Next-Level TIG Welding Technology

TIG DynamicWire – Smart Wire Feeding

At the core of iWave’s TIG innovation is the patented FNS TIG DynamicWire technology. Unlike traditional cold-wire continuous feeding, DynamicWire automatically adjusts wire speed based on real-time current feedback. This ensures precise filler addition, even compensating for up to 30% joint gap tolerance—a capability nearly impossible in conventional TIG welding.

DynamicWire also simplifies setup: operators only define one key parameter (e.g., welding current), while the system self-regulates all others for the perfect weld.

CycleTIG – Controlled Heat Input

With CycleTIG, users gain new control over arc behavior. This function regulates heat input, minimizes discoloration, and produces clean weld seams even on thin sheets or delicate joint geometries. It is especially beneficial for corner welds, butt welds, and repair tasks, where precision is critical.

RPI – Smart Arc Ignition

The integrated Rapid Process Ignition (RPI) reduces arc ignition delay by up to 71%. This guarantees fast, reproducible starts without manual adjustments, regardless of material properties—bringing TIG ignition reliability to an entirely new standard.

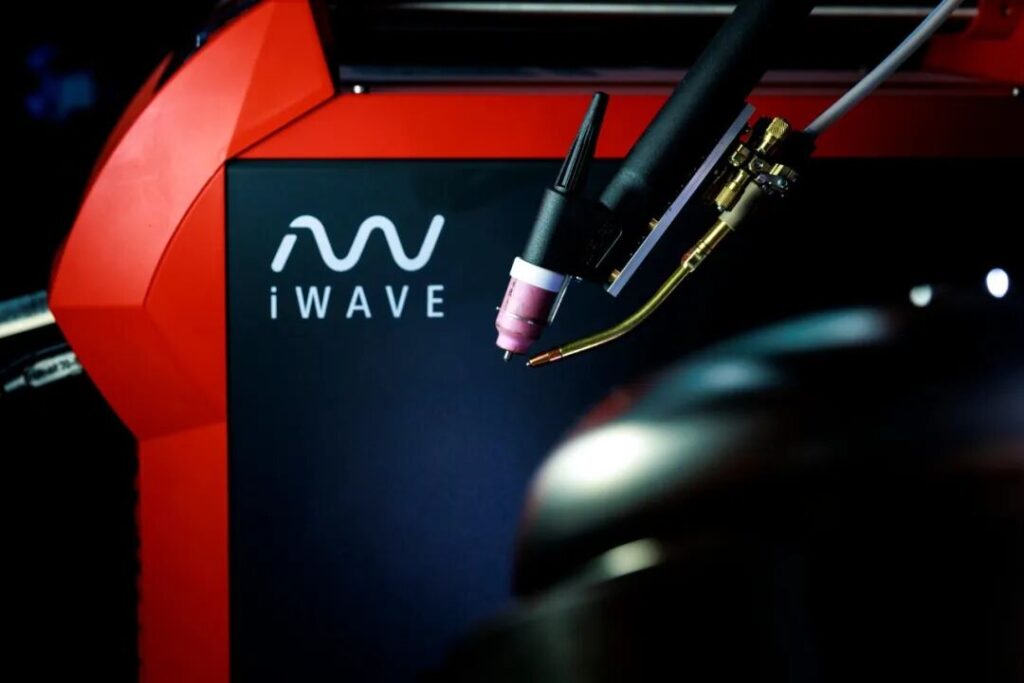

Highlight 2: Multiprocess PRO – One System, Every Process

The iWave 300i, 400i, and 500i models equipped with Multiprocess PRO hardware deliver unmatched flexibility. A single platform can cover TIG and MIG/MAG processes, eliminating the need for multiple machines and reducing workshop space.

Key benefits include:

- Available in DC or AC/DC models with optional water- or air-cooling.

- Support for all FNS process variants: Standard, Pulse, LSC, PMC, and CMT.

- Seamless upgrades to PMC AC, CMT AC, and additive manufacturing for advanced applications.

Whether you’re welding stainless steel tanks, aluminum battery housings, or high-strength steel pipelines, the iWave adapts to your production needs with efficiency and precision.

FNS iWave welding platform

Highlight 3: CMT Advancements for Additive Manufacturing

CMT AC – Lowest Heat Input for Superior Quality

The CMT AC process represents the lowest-heat-input MIG/MAG method available. By reversing wire motion and polarity, it maintains high deposition efficiency while keeping thermal load minimal. This is particularly advantageous for lightweight alloys such as Al-Mg, ensuring shiny, pore-free welds.

CMT Additive Pro – Reliable Layer Building

Specially developed for additive manufacturing, CMT Additive Pro ensures repeatable, uniform weld bead structures across layers. With zero spatter, consistent deposition, and stable geometry, it enables high-quality component building for industries ranging from automotive to energy systems.

Real-World Applications

The FNS iWave Welding Platform enhances productivity and weld quality in:

- Automotive manufacturing (structural parts, battery housings, exhaust systems)

- Pipeline and pressure vessel fabrication

- Lightweight alloy welding for aerospace and EV components

- Additive manufacturing of customized or repair parts

Its versatility makes it the go-to choice for manufacturers seeking both performance and efficiency.

Why Choose the FNS iWave Welding Platform?

- One platform for all major welding processes

- Intelligent self-regulating technologies that reduce operator skill dependency

- Optimized for automation and robotic integration

- Proven cost savings through less rework, higher deposition rates, and space efficiency

FAQ: FNS iWave Welding Technology

Q1: Can iWave be used for both manual and automated welding?

A1: Yes. The robotic-ready iWave builds on the manual version’s success, enabling both standalone and fully automated applications.

Q2: How does TIG DynamicWire improve productivity?

A2: By automatically adjusting filler wire speed to real-time arc conditions, it reduces setup complexity and produces consistent, high-quality TIG welds—even for challenging joint gaps.

Q3: Is the iWave suitable for additive manufacturing?

A3: Absolutely. With CMT AC and CMT Additive Pro functions, the iWave provides low-heat, repeatable layer deposition, ideal for 3D welding applications.

Discover how the FNS iWave Welding technology can transform your welding operations.

👉 Contact our technical team today to request a demo or detailed consultation.