How abrasion resistant cladding extends the service life of mining pipelines?

Mining pipelines are essential to transporting slurries – abrasive mixtures of water and mineral particles — across processing plants, tailings facilities, and transport systems. However, constant exposure to these abrasive slurries subjects pipeline interiors to severe wear. Over time, this results in wall thinning, pinhole leaks, flow inefficiencies, and unexpected failures, increasing maintenance costs and disrupting operations. To protect pipeline systems and maintain efficiency, mining operators increasingly rely on abrasion resistant cladding – a proven solution designed to withstand the harsh realities of abrasive wear.

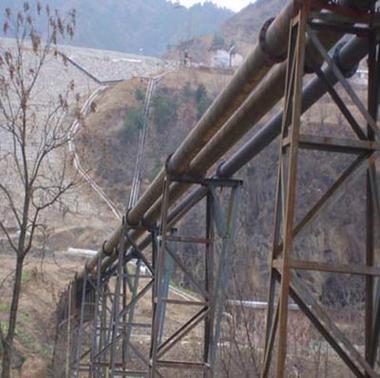

Mining pipeline flanged pipes protected with abrasion resistant cladding

The Causes and Consequences of Mining Pipeline Wear

When slurry flows through a pipeline, hard mineral particles continuously strike and grind against the pipe’s inner surface. This abrasion leads to:

- Wall Thinning: Gradual erosion reduces structural integrity.

- Pinhole Leaks: Small breaches can result in material loss and environmental risks.

- Decreased Flow Efficiency: Rougher surfaces increase friction, raising pumping costs.

- Unexpected Failures: Pipeline ruptures cause costly downtime and emergency repairs.

These challenges highlight the need for durable wear-resistant pipe solutions capable of withstanding continuous abrasive forces.

Abrasion-Resistant Cladding: How It Protects Mining Pipelines

Abrasion-resistant cladding involves metallurgically bonding a wear-resistant alloy onto the internal surface of a pipeline. Unlike standard coatings or liners, cladding creates a robust metallurgical bond with the base metal, providing a durable barrier that resists both mechanical wear and chemical attack.

Key Benefits of Abrasion-Resistant Cladding:

- Superior Wear Resistance: Cladding alloys, typically rich in carbides (like chromium carbides) or other hard compounds, create an incredibly tough surface that can withstand the relentless impact and grinding action of abrasive slurries far better than conventional pipe materials. This dramatically slows down the rate of mining pipeline wear.

- Enhanced Service Life: By providing a sacrificial yet extremely durable layer, abrasion-resistant cladding can extend the operational life of pipelines by several multiples, reducing the need for frequent replacements.

- Reduced Downtime and Maintenance Costs: Less wear means fewer leaks, less need for patching, and significantly reduced unscheduled maintenance. This translates directly into more uptime and lower operational expenditures.

- Optimized Flow Dynamics: A uniformly clad inner surface can maintain a smoother profile for longer, helping to preserve flow efficiency and reduce pumping energy requirements.

- Cost-Effective in the Long Run: While the initial investment in abrasion-resistant mining pipes might be higher than standard pipes, the massive savings from extended lifespan, reduced maintenance, and avoided downtime offer a compelling return on investment.

Where Abrasion-Resistant Cladding Makes a Difference

Abrasion-resistant cladding is particularly beneficial for high-wear areas within mining pipeline systems, including:

- Slurry transport lines: The main arteries carrying abrasive slurries from processing plants to tailings dams or other destinations.

- Concentrate pipelines: Transporting highly abrasive mineral concentrates.

- Pump discharge lines: Areas experiencing high velocity and turbulent flow.

- Elbows and bends: Points where slurry changes direction, leading to concentrated wear.

- Valve bodies: Protecting internal surfaces of valves from erosive flow.

Wear resistant pipe with bonded cladding for slurry transport

Choosing the Right Partner for Slurry Pipeline Protection

Implementing effective slurry pipeline protection requires not just the right technology, but also the right expertise. When considering abrasion-resistant cladding, it’s crucial to partner with a specialized provider who understands the unique demands of mining environments. Look for a company with:

- Deep knowledge of wear mechanisms in slurries.

- Expertise in selecting the optimal cladding alloys for specific abrasive conditions.

- Advanced welding and cladding technologies to ensure metallurgical integrity.

- Proven experience in delivering durable solutions for the mining sector.

By proactively addressing mining pipeline wear with advanced abrasion-resistant cladding, mining operations can significantly enhance their efficiency, reduce costs, improve safety, and ensure uninterrupted production for years to come. It’s an investment in the longevity and resilience of your most critical infrastructure.

Ready to fortify your mining pipelines against the toughest abrasive challenges? Contact FNS Pipeline today to discuss how our abrasion-resistant cladding solutions can extend your equipment’s lifespan and boost your operational efficiency.