Weld overlay cladding extends the service life of industrial components

In demanding industrial environments, equipment frequently battles relentless forces like corrosion, abrasion, and erosion. These aggressive conditions can significantly shorten the lifespan of critical components, leading to costly downtime, frequent replacements, and compromised operational efficiency. Fortunately, there’s a powerful solution that not only protects but also enhances the performance and extends the life of your valuable assets: weld overlay cladding.

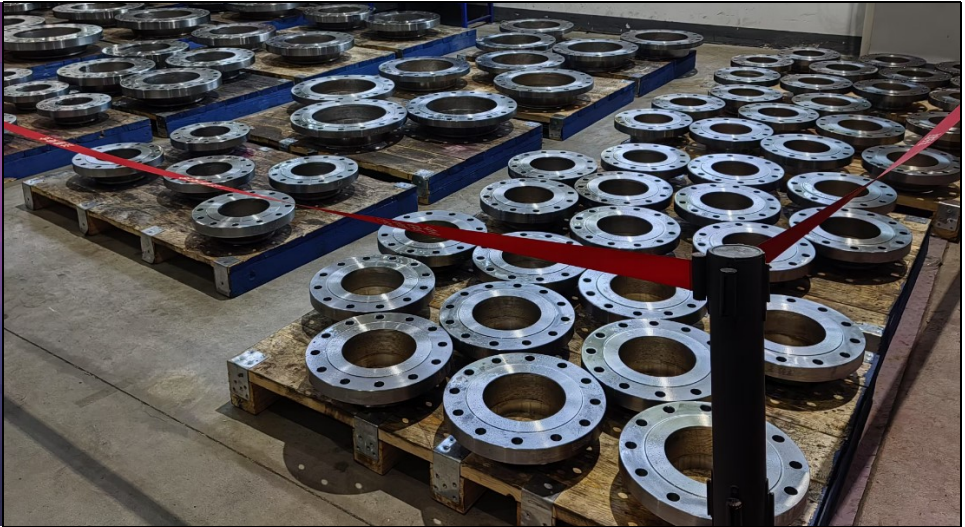

The clad flange products produced by FNS

What Exactly is Weld Overlay Cladding?

Weld overlay cladding is an advanced welding process where a specialized alloy is deposited onto a base material using controlled welding techniques. Unlike surface coatings that adhere mechanically, overlay cladding forms a metallurgical bond, ensuring long-term protection against severe operating conditions.

Common overlay methods include:

- Submerged Arc Welding (SAW)

- Gas Metal Arc Welding (GMAW / MIG)

- Plasma Transferred Arc (PTA) Welding

Material selection depends on the service environment—whether it’s resistance to high temperatures, corrosive chemicals, or severe abrasion. Typical overlay cladding materials include nickel-based alloys, stainless steels, and hardfacing alloys.

Why is Weld Overlay Cladding a Game-Changer for Industrial Assets?

The benefits of implementing weld overlay protection are far-reaching, directly impacting operational costs, safety, and productivity.

Superior Corrosion Resistance: Many industrial processes involve highly corrosive chemicals. Standard materials often succumb to these attacks. Weld overlay cladding with alloys like Inconel 625 or Hastelloy C276 provides an impenetrable barrier, drastically extending the life of components in corrosive environments. This is particularly vital in oil and gas, petrochemical, and chemical processing industries.

Exceptional Abrasion and Erosion Resistance: In sectors like mining, dredging, and power generation, components are constantly exposed to abrasive particles and high-velocity fluids. Applying hard-facing alloys through weld overlay protection creates a resilient surface that resists wear, minimizing material loss and maintaining component integrity. This means fewer breakdowns and consistent performance.

Cost-Effectiveness and Sustainability: While the initial investment in weld overlay cladding might seem higher than traditional repair or replacement, the long-term savings are substantial. By significantly extending the service life of equipment, you reduce the frequency of costly replacements, minimize maintenance downtime, and improve overall operational efficiency. It’s a sustainable solution that preserves capital and resources.

Enhanced Mechanical Properties: Beyond just surface protection, the chosen overlay material can also impart improved mechanical properties to the component’s surface, such as increased hardness or improved fatigue resistance, further bolstering its performance in harsh conditions.

Component Reclamation and Customization: Weld overlay cladding isn’t just for new components. It can also be used to reclaim worn parts, restoring them to original specifications or even enhancing their performance beyond their initial design. Furthermore, the process allows for highly customized solutions, tailoring the cladding material and thickness to precise application requirements.

Flange surfacing equipments

Key Applications Across Industries

At FNS Pipeline, we provide customized weld overlay cladding solutions across various industries:

- Oil & Gas: Protecting pipelines, valves, risers, and pressure vessels from sour gas corrosion and erosion.

- Power Generation: Enhancing boiler tubes, turbine components, and coal pulverizers against high temperatures and abrasion.

- Mining & Metallurgy: Safeguarding chutes, hoppers, grinding mills, and slurry pipes from extreme abrasive wear.

- Chemical & Petrochemical: Lining reactors, tanks, and piping systems to resist aggressive chemical attack.

- Marine & Offshore: Protecting offshore structures and subsea equipment from saltwater corrosion and erosion.

Choosing the Right Partner for Weld Overlay Cladding

When considering weld overlay cladding for your assets, partnering with an experienced and reputable provider is paramount. Look for companies with:

- Proven expertise in material science and welding metallurgy.

- Advanced equipment and stringent quality control processes.

- A track record of successful projects in your specific industry.

- The capability to offer customized solutions tailored to your unique challenges.

By investing in high-quality corrosion-resistant cladding, you’re not just buying a service; you’re investing in the longevity, reliability, and enhanced performance of your industrial equipment, securing your operations for years to come.

Ready to Optimize Your Equipment’s Durability?

Proactive weld overlay solutions prevent costly wear-related failures and extend the operational lifecycle of critical components.Contact FNS Pipeline today to discuss your specific needs and discover customized solutions that protect your investments.