How to reduce welding deformation: a proven method to improve welding quality

Welding deformation is one of the most common challenges in metal fabrication, often resulting in dimensional inaccuracies, reduced structural integrity, and increased production costs. While thermal expansion and contraction during the welding cycle are inevitable, welding distortion can be effectively minimized through smart process design and execution.

In this article, we will explore practical, effective ways to reduce welding deformation, and explain how manufacturers can control shrinkage and maintain dimensional stability in welded assemblies.

1.Avoid Over-Welding

Excessive weld metal not only wastes filler material and time, but also increases the volume of shrinkage during cooling—leading to greater distortion.

Always optimize weld size based on strength requirements. The weld should be flat or slightly convex; excessive buildup doesn’t improve strength but does increase shrinkage stress.

✅ Tip: Smaller, controlled welds = less deformation + cost savings.

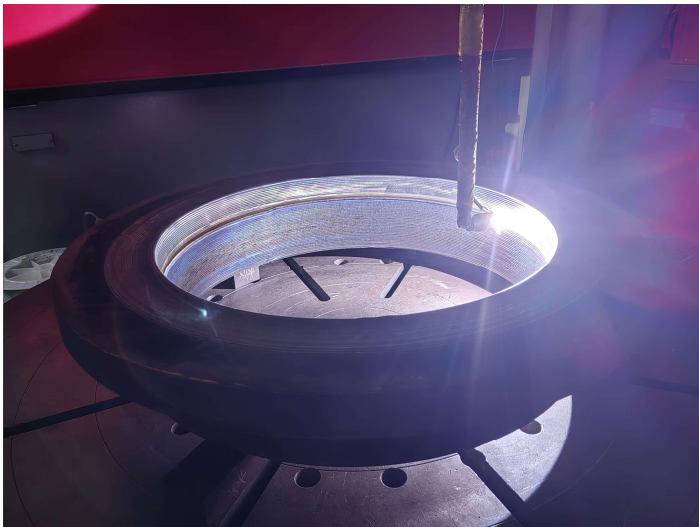

flange overlay cladding

2.Use Intermittent Welds

Intermittent welding (also known as stitch welding) significantly reduces the amount of filler metal while still maintaining structural strength—especially for stiffeners and support plates.

This method can reduce up to 75% of weld volume, minimizing heat input and distortion at the same time.

3.Minimize the Number of Welding Passes

Using thicker electrodes or wire and fewer passes reduces cumulative shrinkage.

Each weld pass contributes to shrinkage, so multi-pass welding amplifies distortion risks.

For carbon steels or low-alloy steels like 16Mn, use thick wire with fewer passes; for stainless steel and high-carbon steels, thin wire and more passes may be preferable.

✅ Welding strategy should always match the base material.

4.Apply Anti-Deformation Techniques

Pre-bending or pre-cambering the workpiece in the opposite direction of expected distortion is a proven way to balance thermal shrinkage forces.

Common anti-deformation practices include:

Pre-setting parts before welding

Using mechanical fixtures or clamps

Symmetrical assembly to balance stress

Strategic placement of wedges for pre-deformation

These methods counteract thermal shrinkage and help maintain flatness after welding.

Valve welding overlay cladding

5.Optimize Welding Sequence

Proper welding sequence is essential to control heat distribution and cumulative stress.

Examples include:

Symmetrical welding from the center outward

Balancing shrinkage with alternating weld directions

Using fixtures to increase stiffness during welds

Back-to-back positioning of identical parts

For small components, welding jigs help reinforce the structure and reduce movement—but they are best suited for ductile materials like low-carbon steel due to the increased restraint forces.

6.Stress Relief After Welding

Peening (light hammering) during or after welding can help stretch the weld bead and reduce residual stress.

However, peening must not be applied to:

Root passes (to avoid cracking)

Final cover passes (to prevent hardening and test interference)

Thermal stress relief methods such as post-weld heat treatment (PWHT) can also be applied to minimize internal stress and ensure better structural stability.

7.Reduce Welding Time

The longer the workpiece is exposed to heat, the more it expands and distorts.

To reduce welding time:

Use mechanized welding to increase speed and consistency

Select appropriate current, electrode size, and travel speed

Shorten heat exposure to large assemblies whenever possible

Faster welds with optimized heat input significantly lower distortion risk.

Final Thoughts: Choose the Right Partner to Improve Welding Quality

Welding distortion may be unavoidable, but with proper techniques, smart planning, and engineering know-how, it can be controlled to a minimum—ensuring better product quality, improved performance, and reduced rework.

At FNS (Nanjing) Surface Engineering Service Co., Ltd., we specialize in advanced welding solutions that reduce deformation and deliver consistent quality. Whether you need arc welding, plasma transferred arc (PTA) overlay, or tailored welding engineering, our team is equipped with the expertise and tools to support your project.

Get in touch today to discover how FNS can help you optimize your welding processes and achieve distortion-free results.