Weld Overlay Quality Control Ensuring FNS Pipeline Products Meet the Highest Standards

In industries such as oil & gas, chemical processing, and power generation, the long-term performance of clad piping depends on more than just material selection—it hinges on meticulous weld overlay quality control. At FNS Pipeline, quality isn’t an afterthought. It’s the core of our manufacturing philosophy. Every pipe we produce is backed by a multi-stage inspection and testing process that ensures unmatched durability, corrosion resistance, and safety in demanding service environments.

Weld overlay process in FNS Pipeline facility with automated systems

Why Weld Overlay Quality Control Matters?

A perfect weld overlay is a complex interplay of material science, precise welding techniques, and rigorous inspection. Any minor deviation can compromise the metallurgical bond, leading to defects like porosity, cracking, or insufficient fusion. In turn, these issues can cause premature product failure in corrosive or abrasive environments.That’s why FNS Pipeline enforces a rigorous quality system—ensuring our weld overlay products not only meet, but exceed, international performance standards.

Key Stages in Weld Overlay Inspection and Testing at FNS

FNS Pipeline implements a multi-faceted weld overlay testing methods, integrating strict inspections and tests throughout the manufacturing process:

1. Incoming Material Inspection:

Before any welding begins, all base pipe and weld overlay filler materials undergo thorough inspection. This includes verifying material certifications, chemical composition, and physical dimensions to ensure they meet specified standards. This foundational step is critical for successful weld overlay quality assurance.

2. Pre-Weld Preparation Verification:

The surface preparation (e.g., cleaning, grinding) of the base pipe is meticulously checked to ensure it’s free from contaminants that could impair bonding. Welding parameters (current, voltage, travel speed) are calibrated and verified according to qualified welding procedures.

3. In-Process Welding Monitoring:

During the actual weld overlay deposition, skilled technicians continuously monitor the entire process. Automated systems track critical parameters to ensure consistency. Visual inspection is performed to check bead shape, overlap, and the absence of any obvious defects. This real-time monitoring is crucial for weld overlay quality assurance.

4. Post-Weld Visual Inspection:

After the overlay is applied, we conduct a detailed visual inspection to identify any surface irregularities, undercuts, overlaps, or visible cracks.

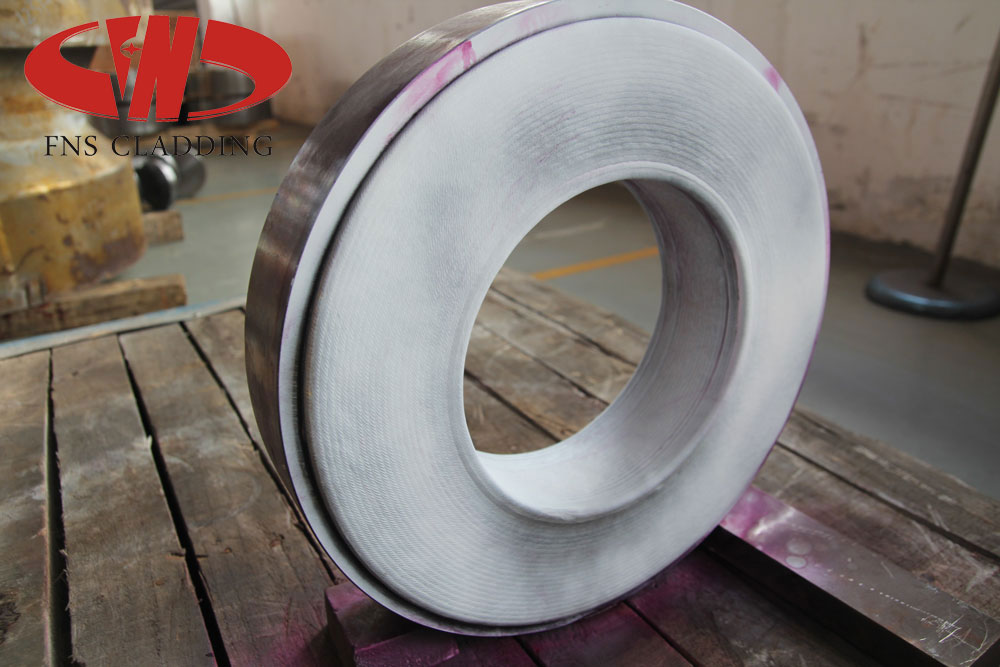

Finished weld overlay flange undergoing Non-destructive testing at FNS

5. Non-Destructive Testing (NDT) in Weld Overlay Inspection:

NDT is the cornerstone for verifying internal integrity without damaging the product. Key methods include:

- Ultrasonic Testing (UT) for Clad Pipes: Highly effective for detecting disbonds, lack of fusion, and other volumetric defects at the interface or within the clad layer.

- Eddy Current Testing: Used for surface and near-surface defect detection.

- Liquid Penetrant Testing (PT) / Magnetic Particle Testing (MT): Used for detecting surface-breaking defects in non-magnetic and magnetic materials, respectively.

- Radiographic Testing (RT): Used for detecting internal defects like porosity or inclusions, especially for critical applications. These NDT techniques are fundamental for rigorous weld overlay quality assurance and weld overlay welding inspection.

6. Mechanical Testing for Weld Overlay Durability:

Sample coupons from the weld overlay pipe or production test pieces undergo destructive mechanical tests, such as bend tests, tensile tests, and hardness tests. This verifies the bond strength, ductility, and the hardness of the overlay layer.

7. Chemical Composition Analysis:

Post-weld chemical analysis of the deposited overlay is performed to confirm that the alloy composition meets specifications, ensuring the desired corrosion or wear properties are achieved. This is particularly important for managing dilution from the base metal.

8. Dimensional Accuracy Verification:

Finally, the dimensions of the finished pipe are checked, including inner diameter, wall thickness, and straightness, to ensure they fully comply with engineering drawings and project requirements.

FNS Pipeline’s Total Commitment to Weld Overlay Quality Assurance

At FNS Pipeline, our comprehensive weld overlay quality control system is integrated into every stage of our manufacturing process. We strictly adhere to international standards and codes, employing certified inspectors and using state-of-the-art testing equipment. This unwavering commitment to weld overlay quality assurance means that every FNS Pipeline product you receive meets the highest standards, providing reliable performance and maximizing the lifespan of your critical infrastructure. Our thorough weld overlay welding inspection brings true peace of mind to our clients.

Looking to ensure long-term reliability of your clad piping systems? Contact FNS Pipeline today and let our certified weld overlay solutions protect your operations—backed by tested quality at every step.