What is dilution rate in weld overlay and why it matters?

In weld overlay and surface engineering, one of the most critical technical parameters—often overlooked—is the dilution rate. This single factor significantly affects the chemical composition, microstructure, and performance of the overlay layer. Whether you’re working with corrosion-resistant alloys, hardfacing materials, or high-temperature coatings, understanding and controlling dilution is essential to ensuring quality and durability.

What is dilution rate in welding?

Dilution rate refers to the proportion of base metal that melts and mixes into the weld pool during overlay or cladding. It’s usually expressed as a percentage and calculated using either weight or cross-sectional area:

Dilution (%) = [Weight of melted base metal / (Weight of melted base metal + weld filler metal)] × 100

Or based on weld cross-sections:

Dilution (%) = [B / (A + B)] × 100

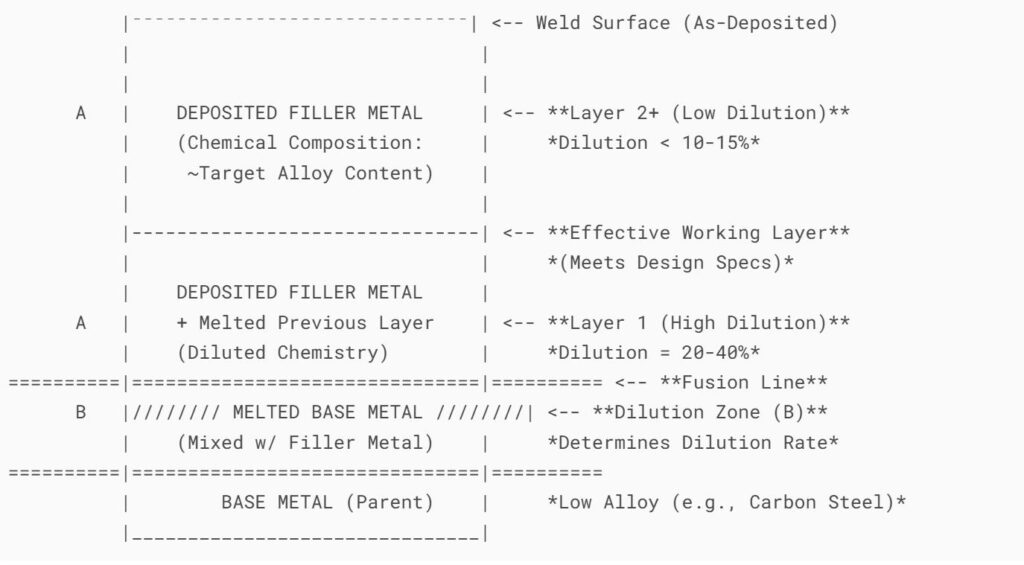

Where:

A = cross-sectional area of the deposited weld metal (from filler)

B = area of base metal melted into the overlay (dilution zone)

A visual representation makes this clearer, but in essence, the more base metal that melts into the weld pool, the higher the dilution rate.

Dilution Rate Drawing

Why dilution rate is so important?

1.It Directly Determines the Final Chemical Composition

Most welding fillers are specially designed to achieve specific corrosion, wear, or heat-resistant properties—commonly using alloys like 309L, 316L, Inconel 625, cobalt-based alloys, and chromium-rich powders.

However, base materials (often carbon steel or low-alloy steel) have little to no alloying elements. When a portion of this base metal melts and mixes into the weld pool, it dilutes the concentration of key elements such as Cr, Ni, Mo, Nb, or C.

For example, if you’re applying 316L (Cr ≈ 17%, Ni ≈ 12%) on carbon steel and experience a 30% dilution, the final weld pool composition might drop to Cr ≈ 11.9% and Ni ≈ 8.4%. That’s far below the intended alloy content—and it significantly reduces corrosion resistance, especially pitting resistance.

2.It Alters Microstructure and Mechanical Properties

High dilution can shift the metallurgical structure:

In stainless steels, insufficient Cr due to dilution may lead to the formation of ferrite or martensite—reducing corrosion resistance and increasing crack susceptibility.

In hardfacing alloys, dilution of C and Cr changes the type and quantity of carbides (like Cr₇C₃), directly impacting hardness and wear resistance.

Mechanical properties like toughness, strength, and ductility are all influenced by these compositional and structural changes.

3.It Affects Effective Layer Thickness

The zone closest to the fusion line—the first pass—is where dilution is highest and performance is lowest. With each additional overlay layer, dilution drops significantly because the “base metal” becomes the previously deposited layer.

The effective working layer is the portion of the weld overlay that truly meets the intended design in terms of composition and performance. It’s usually only the outermost layer.

So, total weld thickness ≠ effective weld thickness. You may need multiple layers (typically 2 or more) to ensure a sufficiently thick, low-dilution, high-performance surface layer.

How to Control Dilution Rate?

1.Choose the Right Welding Process:

| Welding Method | Typical Dilution |

| Submerged Arc (SAW) – single wire | >30% |

| MIG/GMAW – high current | >30% |

| SMAW, FCAW, GTAW (standard) | 15–30% |

| PTA, Laser Cladding, ESW | <15% |

| Optimized TIG, CMT | <10% |

2.Adjust Welding Parameters:

Lower current, voltage, and heat input

Increase travel speed

Use wider weld beads or oscillation

Apply multiple, overlapping passes

3.Select Proper Consumables:

Wider electrode or strip

Bigger diameter wires

Alloy-rich fillers to counter expected dilution

FNS Weld Overlay Cladding Equipment

Why controlling dilution rate is essential?

Performance Assurance: Overlay layers must meet specified chemical and structural standards to resist corrosion, wear, or heat. High dilution undermines those goals.

Cost Efficiency: Excess dilution requires more expensive filler material and additional layers to compensate, raising both material and labor costs.

Avoiding Defects: Improper dilution can lead to formation of brittle phases (like martensite), increasing the risk of weld cracking.

Meeting Standards: Codes like ASME, API, NACE, and RCC-M define allowable chemical compositions and layer thicknesses. These standards can’t be met if dilution is not properly controlled.

Practical Considerations

First Pass Dilution Is Unavoidable: It typically ranges from 20% to over 50%.

Multiple Layers Are Standard: For performance overlays, two or more layers are typically required to achieve a surface dilution below 10%, ideally under 5%.

Welding Procedure Qualification (PQR) Is Mandatory: Always perform chemical analysis, hardness testing, and metallography to confirm that overlay composition and thickness meet project specifications.

Final Thoughts

Dilution rate isn’t just a technical metric—it’s the soul of weld overlay design. Proper understanding and control ensure that the final surface meets the demanding requirements of corrosion, wear, or thermal resistance. Ignoring dilution can turn a high-performance overlay into a superficial layer with substandard performance, risking premature failure and costly downtime.

At FNS Pipeline, we apply strict dilution control in all our welding and cladding projects to guarantee quality and longevity. Whether you’re dealing with stainless overlays, Inconel cladding, or hardfacing, our engineers are ready to help you achieve optimal results.

Looking for reliable weld overlay solutions? Contact FNS Pipeline today for expert support and customized cladding services tailored to your application.