What is the difference between PTA and laser cladding?

In harsh industrial environments, extending component service life and boosting performance is essential. Both Plasma Transferred Arc (PTA) and Laser cladding (Laser Metal Deposition, LMD) techniques enhance corrosion, wear, and heat resistance by applying high-performance overlays, yet they differ significantly in process, application, and cost. As a specialist in welding and cladding technologies, FNS Pipeline offers this technical comparison to help engineers and buyers choose the most suitable solution for their needs.

PTA Cladding

1.Plasma Transferred Arc (PTA) Cladding: The Robust & Efficient Solution

PTA cladding is a highly versatile and robust thermal process that utilizes a constricted, high-energy plasma arc as the heat source. This arc precisely melts a powdered metal filler material and simultaneously fuses it to the surface of the base metal, creating a high-quality, metallurgically bonded overlay. The unique nature of the plasma stream allows for excellent control over the melt pool and material deposition.

Key Characteristics of PTA Cladding:

Heat Input: PTA typically involves a medium to high, but controllable, heat input. This generates a relatively larger melt pool, promoting strong fusion and good wetting between the overlay and the substrate. While effectively creating a robust bond, this higher heat input means careful process control is essential to manage potential distortion, especially on thin-walled or complex geometries.

Dilution Rate: Characteristically, PTA offers good control of dilution, typically ranging from 5% to 15%. This level of dilution is often acceptable for hardfacing applications where a slight intermixing with the base metal doesn’t significantly compromise the overlay’s properties, or can even enhance the bond.

Deposition Rate: PTA boasts a high deposition rate, often ranging from 3 to 8 kg/hr or even higher for specific applications. This makes it a highly efficient and cost-effective choice for applying thick layers over large surface areas.

Overlay Thickness: PTA is well-suited for depositing thicker cladding layers, typically from 1.5 mm to 6 mm or more in multiple passes, providing substantial protection and the ability to reclaim significantly worn components.

Material Versatility: It is highly effective for depositing a wide range of hardfacing materials such as Stellite (cobalt-based alloys), various grades of tungsten carbide, nickel-based alloys, and iron-based alloys. These materials are well-suited for PTA due to their melting characteristics and ability to form robust, wear-resistant layers.

Common Applications of PTA Cladding:

PTA cladding is widely favored for components requiring robust wear and erosion resistance, especially those with thicker sections or larger areas:

Valve Seats and Sealing Surfaces: Providing durable protection against galling and erosion in critical flow control applications.

Pump Impellers, Shafts, and Casings: Enhancing resistance to abrasion and erosion from slurries in fluid handling.

Downhole Tools and Drill Bits: Fortifying surfaces against extreme abrasion and impact in oil & gas drilling.

Mining and Cement Industry Wear Parts: Including crusher hammers, mill liners, and industrial rollers, where high deposition rates and thick, hard layers are essential.

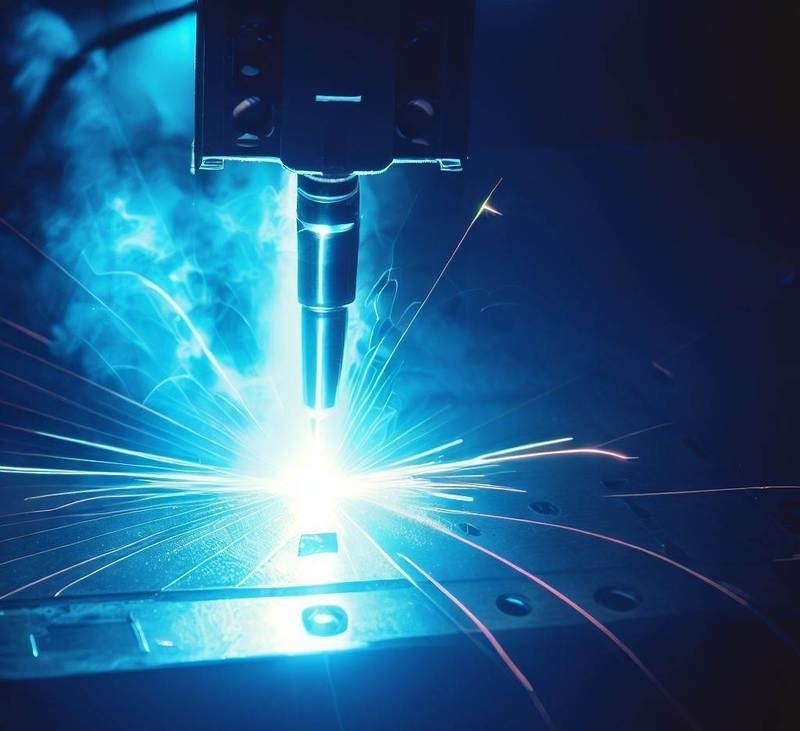

2.Laser Cladding: The Precision and Minimal Distortion Specialist

Laser Cladding

Laser Cladding, also known as Laser Metal Deposition (LMD) or Laser Hardfacing, employs a highly focused laser beam as the heat source. The laser precisely melts a very shallow layer of the base metal’s surface while simultaneously feeding metallic powder or wire into the melt pool. This creates a thin, high-performance overlay with exceptional metallurgical integrity. The rapid solidification inherent in laser cladding results in a refined microstructure.

Key Characteristics of Laser Cladding:

Heat Input: Laser cladding is characterized by extremely low and highly localized heat input. The laser energy is concentrated in a very small area, leading to rapid heating and cooling cycles. This significantly minimizes the Heat Affected Zone (HAZ) in the base material and drastically reduces thermal distortion.

Dilution Rate: One of the most significant advantages of laser cladding is its extremely low dilution rate, typically less than 2% (often below 1%). This precise control ensures that the deposited alloy’s chemical composition remains virtually uncompromised by the base metal, which is critical for maintaining the full properties of expensive, high-performance alloys.

Deposition Rate: Compared to PTA, laser cladding generally has a moderate to low deposition rate (e.g., 0.1-2 kg/hr). Its strength lies in precision and minimal distortion rather than bulk material deposition.

Overlay Thickness: Laser cladding is ideal for creating thin, precise cladding layers, typically ranging from 0.2 mm to 2 mm. This capability allows for highly accurate build-ups on complex geometries.

Metallurgical Bond & Microstructure: It produces an excellent metallurgical bond with the substrate, characterized by a very dense and fine-grained microstructure due to the extremely rapid solidification rates. This often translates to superior wear and corrosion performance.

Precision & Distortion Control: Laser cladding offers unmatched precision and minimal distortion, making it ideal for treating components with intricate shapes, thin walls, or tight dimensional tolerances that cannot tolerate significant thermal stress.

Common Applications of Laser Cladding:

Laser cladding excels in high-value, precision applications where minimal distortion, exact material properties, and superior surface finish are paramount:

Aerospace Components: Such as turbine blades, engine parts, and landing gear components, where high performance, minimal weight, and exceptional integrity are critical.

Medical Implants: Applying biocompatible coatings to prosthetics and surgical tools, demanding high precision and purity.

Precision Molds and Dies: Enhancing surface hardness and wear resistance for tools used in manufacturing.

Turbine Blades and Sealing Rings in Power Generation: Providing high-temperature, wear-resistant coatings with minimal distortion for energy efficiency.

Components with Complex Geometries or Thin Walls: Where conventional welding processes would cause unacceptable distortion or damage.

3.PTA Cladding vs. Laser Cladding: A Head-to-Head Technical Comparison

Understanding the nuanced differences between PTA and laser cladding is key to selecting the optimal process for your specific industrial application.

| Feature | PTA Cladding | Laser Cladding |

| Heat Input | Medium to High (larger, more dispersed melt pool) | Very Low (highly localized, rapid cooling) |

| Dilution Rate | ~5–15% (Controllable, acceptable for many robust layers) | Extremely Low (<2%, often <1%) |

| Deposition Rate | High (up to 5–8 kg/hr or more) | Moderate to Low (0.1-2 kg/hr typical) |

| Overlay Thickness | 1.5–6 mm (or thicker, robust layers) | 0.2–2 mm (thin, precise layers) |

| Metallurgical Bond | Strong, dense, low porosity | Excellent, dense, very fine-grained microstructure |

| Heat Affected Zone | Larger, more pronounced HAZ | Minimal, highly localized HAZ |

| Microstructure | Generally coarser grain structure | Very fine, refined grain structure (rapid solidification) |

| Distortion Risk | Higher risk of distortion, especially on delicate parts | Minimal distortion, ideal for precision components |

| Surface Finish | Typically requires more post-cladding machining to achieve final tolerance | Often near-net-shape, requiring minimal post-processing |

| Equipment Cost | Generally lower initial investment | Higher initial investment |

| Operating Cost (per kg) | Generally lower per kg of deposited material | Generally higher per kg of deposited material |

| Suitable Materials | Broad range of hardfacing alloys (WC, Stellite, Ni-based, Fe-based) | High-performance alloys, CRAs, superalloys (Ni, Co, Ti-based, carbides) |

4.Strategic Selection: How to Choose Between PTA and Laser Cladding

The decision between PTA and laser cladding at FNS Pipeline is always data-driven and tailored to your specific project requirements. We consider the following critical factors:

Primary Degradation Mechanism: Is the main challenge severe abrasion/impact over large areas (often PTA) or precision wear/corrosion/high-temperature resistance on critical surfaces (often Laser)?

Component Geometry & Material Sensitivity: For large, robust components or those needing thick, cost-effective layers, PTA’s efficiency shines. For intricate, thin-walled, or distortion-sensitive parts made from heat-sensitive alloys, laser cladding’s precision is unmatched.

Required Overlay Properties: Does your application demand extremely low dilution to preserve specific material properties (Laser), or is a slightly higher but controlled dilution acceptable for a robust hardfacing layer (PTA)?

Cost-Benefit Analysis: PTA generally offers a lower cost per kilogram of deposited material, making it suitable for high-volume, cost-sensitive applications. Laser cladding, while having higher per-kilogram costs, often results in less material waste and significantly reduced post-processing, leading to overall savings for high-value precision parts.

Desired Surface Finish & Post-Processing: If a near-net-shape finish with minimal post-machining is crucial, laser cladding is the ideal choice.

5.Why Choose FNS Pipeline for Your Advanced Cladding Needs?

FNS Pipeline is more than just a service provider; we are your strategic partner in optimizing the longevity and performance of your industrial assets. Our expertise in both PTA and Laser Cladding, combined with our rigorous quality control and customer-centric approach, sets us apart:

Dual-Technology Mastery: We operate both state-of-the-art PTA and Laser Cladding systems, giving us the unique ability to objectively recommend and apply the most suitable technology based on your specific component, degradation mechanism, and performance requirements, ensuring an optimized solution.

In-house Metallurgical Laboratory & Rigorous Testing: Our dedicated materials lab is equipped for advanced metallurgical analysis. We conduct comprehensive testing including microstructure analysis, dilution assessment, HAZ evaluation, hardness mapping, specialized wear testing (e.g., ASTM G65 for abrasion), and various corrosion tests (e.g., ASTM G48 for pitting/crevice corrosion). This ensures that every cladding solution performs precisely as intended.

Custom Engineered Solutions: We don’t believe in one-size-fits-all. Our experienced engineers and metallurgists collaborate closely with you to understand your exact service conditions, analyze failure modes, and design bespoke overlay solutions optimized for your component’s unique operating environment and desired lifespan.

Uncompromising Quality & Compliance: FNS Pipeline adheres to the highest global standards, including NACE MR0175/ISO 15156 (for sour service environments), ISO 14700 (for thermal spraying and hardfacing), and API 6A (for wellhead and Christmas tree equipment). Our certified welders and meticulously qualified processes ensure unparalleled quality, reliability, and full traceability.

Proven Industry Leadership: Trusted by clients in the demanding offshore oil & gas, chemical processing, power generation, and hydrogen energy sectors, we consistently deliver solutions that extend component lifespan, reduce maintenance costs, and enhance operational safety and efficiency, making us a leader in surface engineering.

For expert consultation on whether PTA or laser cladding is the right solution for your project, contact FNS Pipeline today. Visit our website to explore our comprehensive range of advanced surface engineering and weld overlay solutions.